XZ Belt Used for Packing and Printing Industry

Updated: 2022-7-12

Xuanze Industrial Drive Systems (Shanghai) Co., Ltd. is a Shanghai high-tech enterprise that produces conveyor belts and transmission belts. The company has a standard production workshop of 20000 square meters, 40 employees and 6 sales and service personnel. It has more than ten independent invention patents for industrial belts, and has developed super-wear-resistant paper conveyor belts (Feida belts) for the printing cardboard industry, super-wear-resistant patterned cardboard conveyor belts, and easy-to-connect conveyor belts, which can fundamentally solve problems such as difficult installation and disassembly of belts. Tests have shown that the service life of the belts exceeds that of imported belts, breaking the monopoly of Europe and the United States in this industry, and is superior to similar European and American products in application.

The factory has a large inventory to meet customer needs as quickly as possible, and has advanced and sophisticated testing equipment to ensure product quality. The company has always insisted on independent product development, catching up with first-class foreign quality, continuous innovation, breaking through tradition, and in order to produce high-quality products suitable for customers, all employees are committed to contributing their own strength to the development of China's industry.

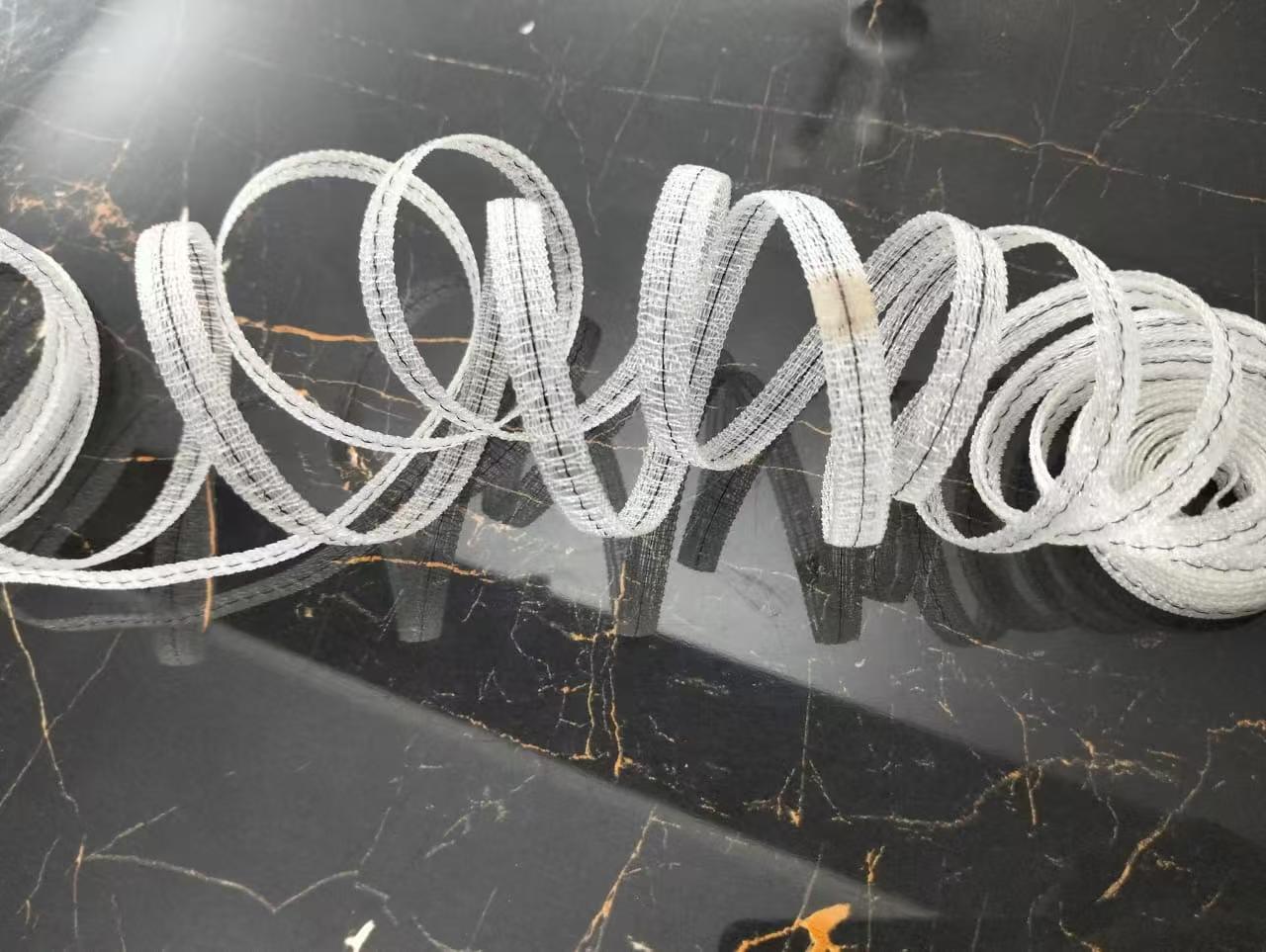

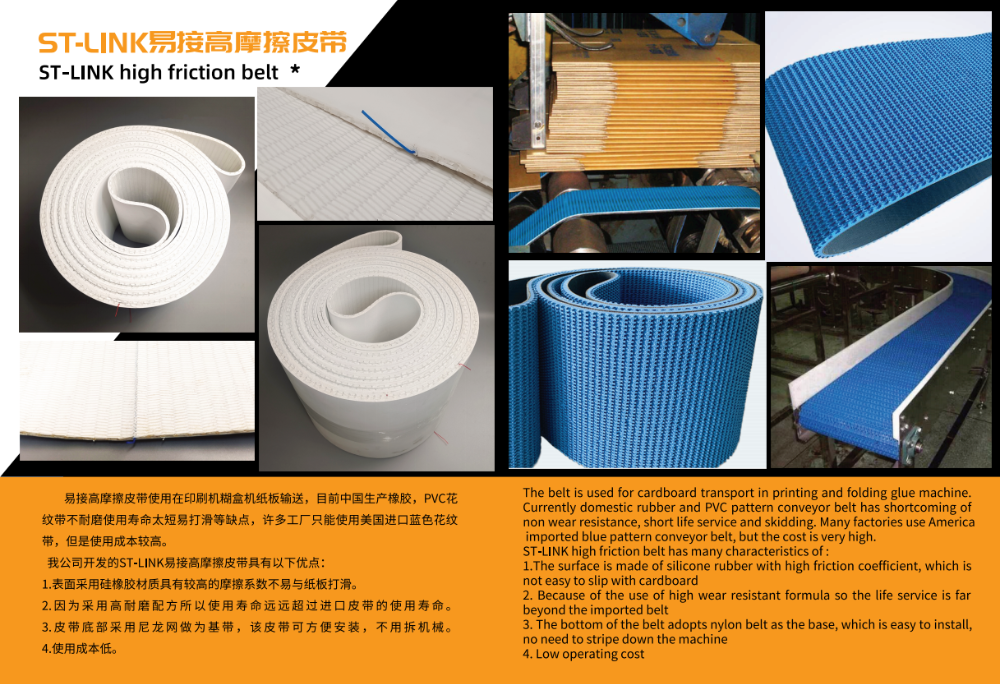

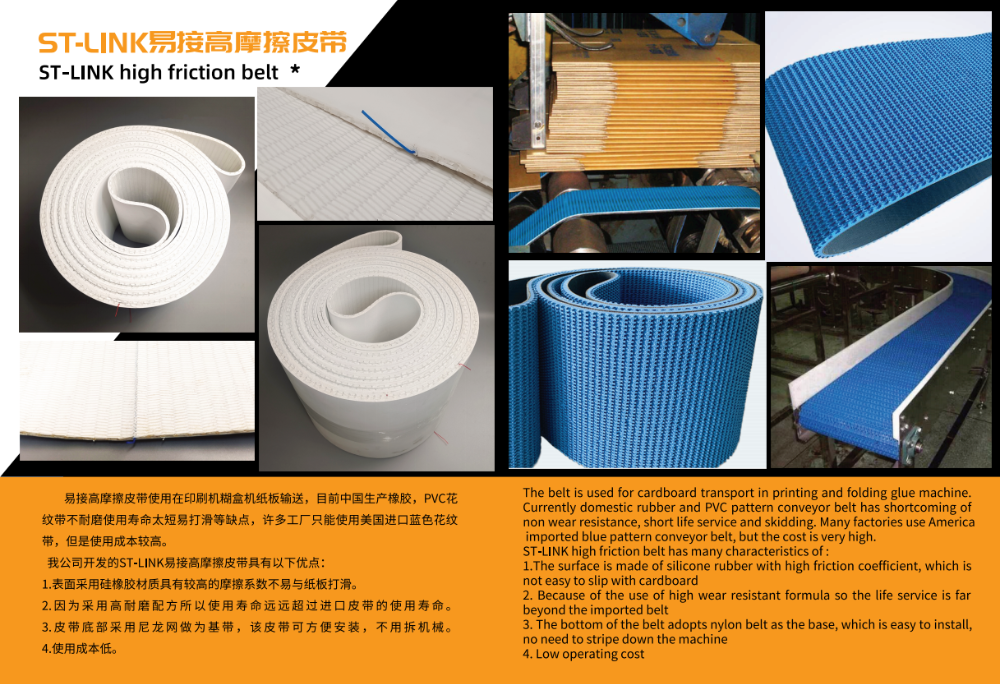

Feeder belts are used in the front section of folder-gluers. These belts are typically around 28mm wide and typically come in groups of four. Currently, domestically produced rubber belts lack wear resistance and suffer from slippage. Imported belts from the United States and Japan can generally meet these requirements, but they're not ideal. SIW super-wear-resistant feeder belts offer excellent friction, exceptional wear resistance, and are soft and non-marking. Easy-to-connect high-friction belts are used for cardboard conveying in folder-gluers on printing presses. Currently, Chinese-made rubber and PVC patterned belts lack wear resistance, have a short service life, and are prone to slippage. Many factories are forced to use imported blue patterned belts from the United States, but these belts are more expensive.

Our company's ST-LINK easy-to-connect, high-friction belt offers the following advantages: 1. Its surface is made of silicone rubber, offering a high coefficient of friction and resisting slippage with cardboard. 2. Its highly wear-resistant formula significantly extends its service life compared to imported belts. 3. Its nylon mesh base allows for easy installation without disassembling machinery. 4. Its cost-effectiveness is low.

Double-sided blue high friction base belt, both sides are blue rubber, and the middle is a strong black base. The blue rubber surface can provide good friction and can effectively carry out conveying work. The whole belt has high strength and low elongation. It has the advantages of softness, high speed, stability, low noise, high strength, not easy to stretch, firm connection and no cracking. Common thicknesses are 3mm, 4mm, and 6mm. Flat cardboard conveyor belts have high strength, cut resistance, and good wear resistance. They can be made into circular seamless or connected, meet hygiene indicators, have moderate color, and are lightweight and durable. The surface of the belt can be smooth or matte. We mainly have white, dark green and blue-green. The belt can be added with baffles, guides, sidewalls and sponges according to customer requirements.

Substantial inventory ensures fast delivery

Advanced testing equipment guarantees product quality

Continuous innovation and development surpass international standards

Dedicated to improving China’s industrial efficiency and global competitiveness

XZ Belt provides reliable, durable, and high-performance conveyor solutions for the packing and printing industry. From feeder belts to customized flat conveyor belts, our products optimize productivity, reduce maintenance, and deliver consistent performance.

The factory has a large inventory to meet customer needs as quickly as possible, and has advanced and sophisticated testing equipment to ensure product quality. The company has always insisted on independent product development, catching up with first-class foreign quality, continuous innovation, breaking through tradition, and in order to produce high-quality products suitable for customers, all employees are committed to contributing their own strength to the development of China's industry.

Feeder belts are used in the front section of folder-gluers. These belts are typically around 28mm wide and typically come in groups of four. Currently, domestically produced rubber belts lack wear resistance and suffer from slippage. Imported belts from the United States and Japan can generally meet these requirements, but they're not ideal. SIW super-wear-resistant feeder belts offer excellent friction, exceptional wear resistance, and are soft and non-marking. Easy-to-connect high-friction belts are used for cardboard conveying in folder-gluers on printing presses. Currently, Chinese-made rubber and PVC patterned belts lack wear resistance, have a short service life, and are prone to slippage. Many factories are forced to use imported blue patterned belts from the United States, but these belts are more expensive.