XZ Belt Automotive Stamping Conveyor Belts

Updated: 2022-7-12

In the modern automotive industry, precision, cleanliness, and efficiency are non-negotiable requirements for stamping and sheet-metal production lines. Every step—from uncoiling to blanking—demands conveyor systems that can maintain a contaminant-free environment and stable operation. Traditional PU belts, however, often suffer from surface peeling and dust generation, leading to production interruptions and potential defects in metal sheets.

To address this long-standing issue, Xuanze Industrial Drive Systems (Shanghai) Co., Ltd. has developed the KT30-Y Anti-Chip Conveyor Belt, a breakthrough innovation that redefines reliability in automotive stamping lines.

Xuanze Industrial Transmission Systems Co., Ltd. was established in Shanghai in 2013. It is a modern technology enterprise specializing in the research and development and manufacturing of industrial conveyor belts. The company’s main products include PU/PVC conveyor belts, felt belts, flat belts, and timing belts, with several advanced product lines such as seamless belts, Ziplink belts, steel industry helping roller belts, and silicone timing belts.

With over ten invention patents and recognition as a Shanghai High-Tech Enterprise (2019), Xuanze continuously drives industrial progress through independent innovation. The company has also achieved ISO9001 quality management and ISO14001 environmental management certifications, ensuring that every belt produced meets global standards of safety, durability, and environmental responsibility.

In automotive stamping production, body parts require extremely high surface finish and precision. Traditional PU conveyor belts often generate dust and debris during stamping and conveying due to strong impact, cutting, or friction. These tiny PU particles not only pollute the production line environment but can also scratch the steel surface, affecting coating adhesion and even requiring equipment downtime for cleaning. For a long time, these chip-resistant conveyor belts have been monopolized by European and American brands. Their high price and long lead times have resulted in high operating and maintenance costs for many manufacturers.

Xuanze’s KT30-Y PU Anti-Chip Conveyor Belt has effectively ended the era of belt chipping—not only outperforming domestic competitors but also surpassing similar European and American products in durability and cleanliness.

Key Advantages:

Anti-Chip Performance: Reduces belt dust and particles by more than 80% compared to standard PU belts.

Durability: Resistant to impact, abrasion, and cutting, ideal for high-pressure stamping lines.

Clean Transfer: Ensures clean sheet surfaces without belt contamination.

Longer Service Life: Extended operation cycles with minimal maintenance downtime.

By solving the chip issue at its root, KT30-Y belts significantly improve production stability and product yield, while reducing cleaning costs and environmental waste.

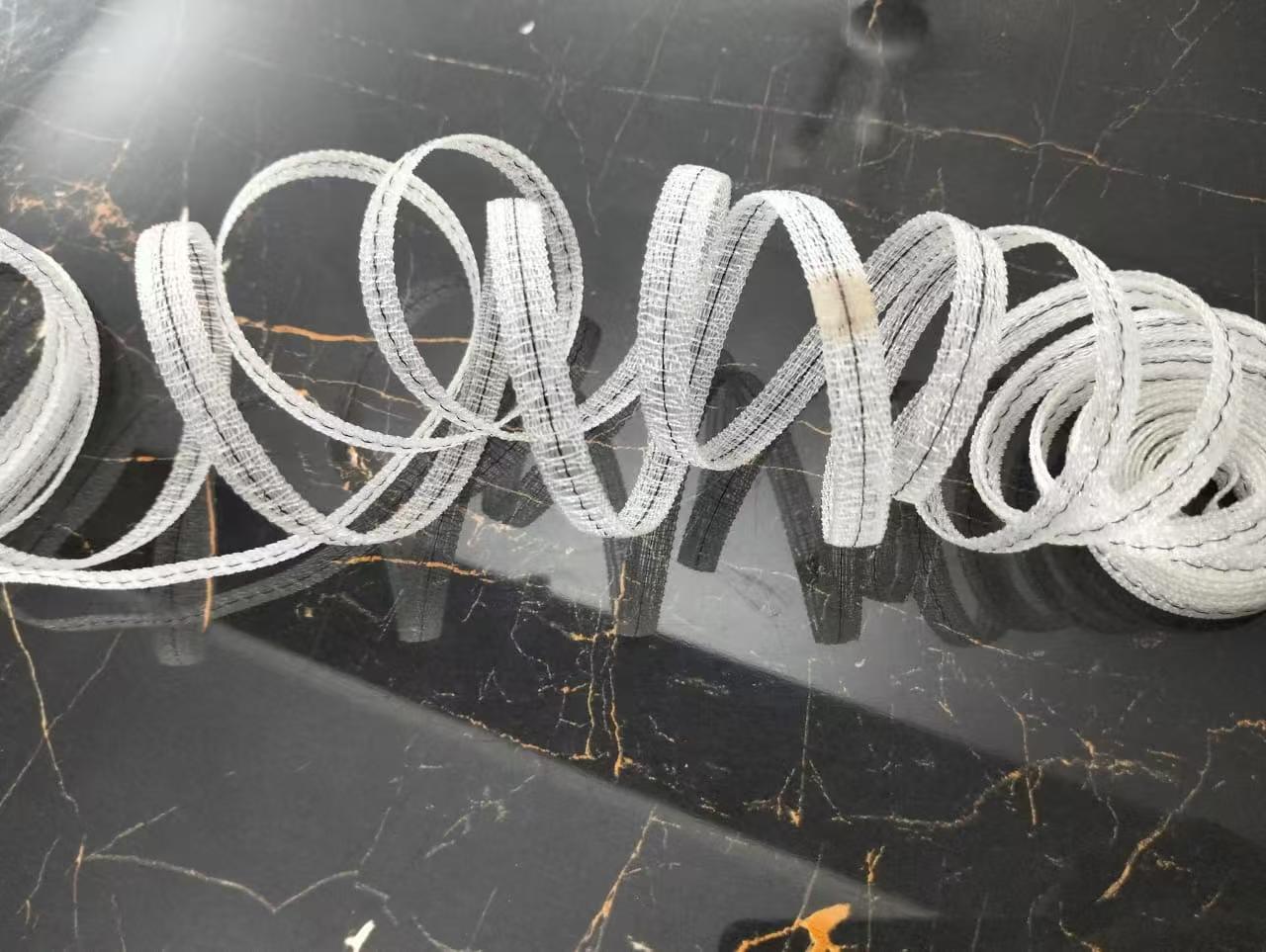

For steel plate uncoiling and blanking production lines, Xuanze introduced the RX40-RE red seamless conveyor belt, designed specifically for precision feeding. Featuring a chip-resistant and wear-resistant formula, this belt effectively reduces belt debris by over 90%, maintaining a clean and safe production environment even at high speeds.

The RX40-RE is particularly well-suited for retractable flat belt feeding systems, excelling in conditions requiring stable friction and dimensional accuracy. Its excellent tensile strength and temperature resistance ensure excellent transmission stability and service life even under high-frequency operation and long-term continuous operation.

Another flagship innovation from Xuanze is its magnetic timing belt series, designed specifically for automotive factories and steel plate processing centers.

Using BASF PU material and Bekaert steel cords, these belts are produced through integrated injection molding, providing:

Excellent magnetic permeability

High cut resistance

Precise synchronous transmission

They are widely applied in automated production lines of top manufacturers such as Schuler (Germany), FAGOR (Spain), Siemens, AIDA (Japan), JIER, Aotto, and Taiwan King-Fung, among others.

Xuanze’s production base is equipped with advanced manufacturing machinery, complete inspection systems, and rigorous testing protocols. Every belt undergoes comprehensive quality checks to guarantee consistency and reliability.

The company’s technical team is committed to developing solutions tailored to customer needs, continuously refining materials, processes, and belt performance to meet the ever-growing demands of automotive, steel, and logistics industries.

With the KT30-Y and RX40-RE series, Xuanze Industrial Drive Systems has successfully broken the monopoly of Western brands and proven that Chinese innovation can lead the global market in high-performance industrial belts.

From automotive stamping to steel sheet handling, Xuanze’s PU non-chip conveyor belts deliver exceptional reliability, durability, and cleanliness, empowering manufacturers to achieve higher productivity and better product quality.

To address this long-standing issue, Xuanze Industrial Drive Systems (Shanghai) Co., Ltd. has developed the KT30-Y Anti-Chip Conveyor Belt, a breakthrough innovation that redefines reliability in automotive stamping lines.

1. Company Background: A Leading Innovator in Conveyor Technology

2. The Problem: Chip Shedding in Automotive Stamping Lines

In automotive stamping production, body parts require extremely high surface finish and precision. Traditional PU conveyor belts often generate dust and debris during stamping and conveying due to strong impact, cutting, or friction. These tiny PU particles not only pollute the production line environment but can also scratch the steel surface, affecting coating adhesion and even requiring equipment downtime for cleaning. For a long time, these chip-resistant conveyor belts have been monopolized by European and American brands. Their high price and long lead times have resulted in high operating and maintenance costs for many manufacturers.

3. The Solution: KT30-Y Anti-Chip Conveyor Belt

4. RX40-RE Seamless Red Belt: Designed for Sheet-Metal Feed Lines