The Ultimate Guide to Coil Wrapper Belts: Structure, Applications, and Why xzbelt Leads the Industry

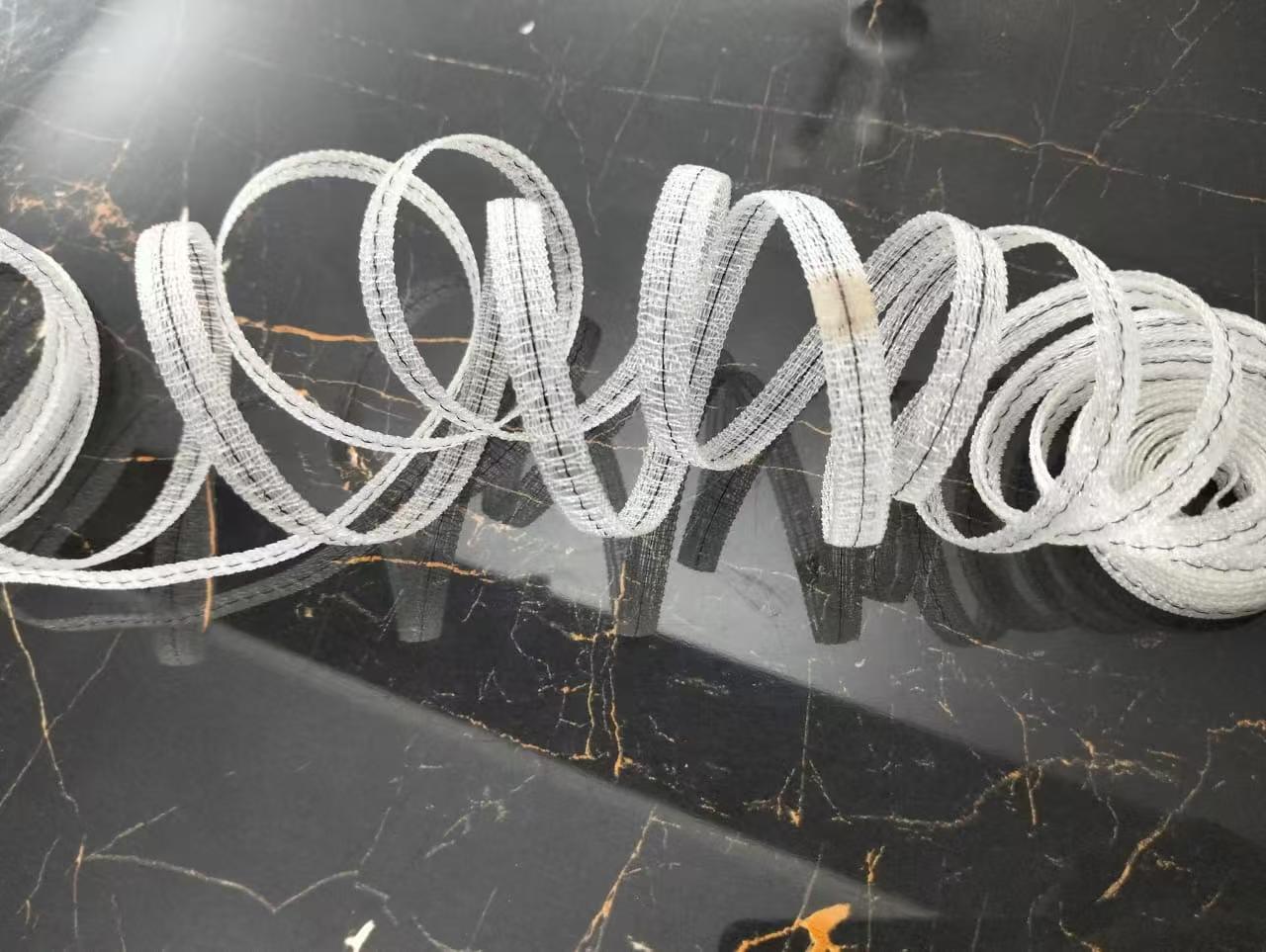

In modern steel and aluminum coil production, the stability of coil wrapping directly affects product quality, production efficiency, and equipment lifespan. Among the core components of coil wrapping systems, the Coil Wrapper Belt plays a critical role. It ensures tight, uniform, and slip-free winding of steel and aluminum strips during cold rolling, hot rolling, or acid pickling processes.

As an industry-leading conveyor belt manufacturer, xzbelt has independently developed a series of high-performance coil wrapper belts, including UU-STL5, UUX50-GW, UUX70-GW, UUX80-GW, RUX80-GW for pickling lines, and KM80-Y for hot rolling applications. These products are now widely used in steel mills, aluminum mills, and global coil processing plants.

This blog provides a deep dive into how Coil Wrapper Belts work, their structural differences, technical parameters, and why xzbelt stands out as a trusted supplier.

What Is a Coil Wrapper Belt?

A Coil Wrapper Belt is a specialized high-friction, wear-resistant belt used in auxiliary coiler units to improve the tightness and stability of metal coils during winding. Unlike traditional rubber belts that tend to absorb oil, deform, slip, or deteriorate under heat and emulsion, coil wrapper belts use advanced PU/TPU/Ropan elastomers and reinforced carcass fabrics to ensure:

-

High friction

-

Excellent tensile strength

-

Dimensional stability

-

Resistance to oil, heat, emulsion, acid fumes

-

Consistent performance at high speed

They are indispensable in:

-

Steel cold rolling lines

-

Aluminum coil lines

-

Pickling lines

-

Hot rolling finishing equipment

-

Packaging and recoiling units

Structural Design of Coil Wrapper Belts

Although different process lines require different models, xzbelt’s coil wrapper belts share a common engineering philosophy:

High friction + high strength + high durability + custom thickness design

1. Surface Cover Material

Depending on the model:

-

TPU (e.g., UU-STL5) – extremely wear-resistant, flexible, oil-resistant

-

PU (UUX series) – stable and smooth friction, suitable for aluminum coils

-

Ropan elastomer (RUX series) – resistant to acid fumes and emulsions

-

Heat-resistant compounds (KM80-Y) – designed for hot rolling applications

The surface material is engineered to provide a consistent friction coefficient of 0.8, preventing coil slippage.

2. Reinforcement Layer (Carcass)

Different production lines require different reinforcement structures:

-

Stainless-steel mesh (UU-STL5) for extremely high strength

-

High-strength polyester fabric (UUX70-GW, UUX80-GW)

-

Standard polyester fabric (UUX50-GW)

-

High-strength textile layers with Ropan (RUX80-GW)

The carcass determines the belt’s tensile performance, elongation recovery, and overall lifespan.

3. Thickness and Hardness

xzbelt coil wrapper belts typically come in:

-

Thickness range: 4–10 mm

-

Hardness: 80–90 A

-

Speed capability: 380–400 m/min

-

Tension range: 30–80 N/mm (1% stretch strength)

Customers can also request custom thickness for specific coiling tension and roller gap requirements.

Comparison of Major xzbelt Coil Wrapper Belt Models

Below is a simplified comparison based on your technical files:

| Model | Material Structure | Reinforcement | Thickness | 1% Stretch | Tensile | Speed | Friction | Application |

|---|---|---|---|---|---|---|---|---|

| UU-STL5 | TPU/TPU | Stainless-steel mesh | 10 mm | 50 N/mm | 350 N/mm | 380 m/min | 0.8 | Cold-rolled steel |

| UUX50-GW | PU/PU | Polyester | 4–10 mm | 30 N/mm | 300 N/mm | 400 m/min | 0.8 | Light-load aluminum |

| UUX70-GW | PU/PU | High-strength polyester | 4–10 mm | 50 N/mm | 350 N/mm | 400 m/min | 0.8 | Medium-load aluminum |

| UUX80-GW | PU/PU | High-strength polyester | 4–10 mm | 50 N/mm | 350 N/mm | 400 m/min | 0.8 | Heavy-load, high-speed aluminum |

| RUX80-GW | Ropan elastomer | Polyester | 4–10 mm | 80 N/mm | 400 N/mm | 400 m/min | 0.8 | Acid pickling lines |

| KM80-Y | Heat-resistant compound | Textile layers | 8–10 mm | — | — | — | — | Hot rolling aluminum |

This portfolio enables xzbelt to meet the full spectrum of coil production processes—from high-temperature hot rolling to chemically aggressive pickling environments.

Where Coil Wrapper Belts Are Used

1. Steel Cold Rolling Lines

Requires strong friction and high tension resistance.

Best choices: UU-STL5 / UUX70-GW / UUX80-GW

2. Aluminum Coil Production

Needs soft friction, anti-scratch layers, and stable tension.

Best choices: UUX50-GW / UUX70-GW / UUX80-GW

3. Acid Pickling Lines

Environment contains acid mist, oil, emulsions—standard PU belts degrade quickly.

Best choice: RUX80-GW

4. Hot Rolling and Finishing Mills

High temperature + high tension requires special materials.

Best choice: KM80-Y

Why xzbelt Leads the Coil Wrapper Belt Industry

1. Independent R&D and Full Process Control

Unlike many trading companies, xzbelt operates a 30,000m² modern factory specializing in conveyor belts and special belts. From raw materials to molding and final testing, every production stage is controlled internally.

2. Advanced Manufacturing Techniques

xzbelt applies industry-leading technologies including:

-

Seamless endless molding

-

High-temperature bonding

-

Anti-emulsion composite coating

-

Precision thickness control

-

CNC guiding and cutting

These processes guarantee durability and consistency across all belt models.

3. Material Innovation

The RUX and KM series use custom elastomer compounds such as Ropan and heat-resistant materials that outperform traditional rubber and standard PU belts in harsh industrial environments.

4. Proven Reliability

xzbelt belts are used by major steel mills, aluminum plants, and equipment integrators worldwide. Strong tensile performance, stable friction, and long lifespan significantly reduce downtime and operating costs.

5. Comprehensive Product Portfolio

Whether your line is:

-

Cold rolling

-

Hot rolling

-

Pickling

-

Aluminum finishing

-

High-speed recoiling

-

Packaging lines

xzbelt offers a tailor-made coil wrapping belt for your specific requirements.

How to Select the Right Coil Wrapper Belt

To choose the correct model, consider:

-

Type of coil material

-

Steel vs. aluminum vs. pickled strip

-

-

Line speed (m/min)

-

Tension requirement (N/mm)

-

Environmental condition

-

High temperature

-

Acid/emulsion/oil

-

High humidity

-

-

Desired lifespan and maintenance cycle

-

Required belt thickness

xzbelt engineers can assist you in selecting the most suitable model based on your machine type and production environment.

Conclusion

Coil Wrapper Belts are indispensable components in metal coil production. With the increasing demand for high-speed, high-precision, and high-reliability coil processing, choosing the right belt is more important than ever.

xzbelt’s comprehensive and independently developed portfolio—including UU-STL5, UUX series, RUX80-GW, and KM80-Y—offers industry-leading performance, durability, and customization capability, making xzbelt one of the most trusted suppliers for steel and aluminum coil manufacturers worldwide.

If you’re looking to enhance your production stability, reduce downtime, and extend belt lifespan, xzbelt provides a full-suite solution backed by advanced manufacturing and strong R&D.