In cigarette manufacturing, Garniture tape is often treated as a consumable part.

In reality, it is one of the most critical components affecting cigarette quality and machine stability.

Most customers contact us with a simple request:

they want to order Garniture tape for their tobacco machines.

But once we start discussing machine speed, production rhythm, and forming stability, it becomes clear that Garniture tape selection is rarely a simple replacement decision.

Why Garniture Tape Matters in Daily Production

During cigarette rod forming, Garniture tape directly controls how tobacco is guided and shaped.

If surface friction is inconsistent, the cigarette rod may look acceptable at first, but variations in firmness and diameter will gradually appear during long production runs.

We have seen situations where operators continuously adjust machine parameters, trying to stabilize production, without realizing that the Garniture tape surface has already changed due to wear. Once the surface becomes polished or uneven, stable forming becomes difficult no matter how carefully the machine is adjusted.

A properly selected Garniture tape provides controlled and uniform friction, allowing the machine to run steadily over extended periods without constant fine-tuning.

Service Life Is Not Only About Speed

One of the most common complaints we hear is that Garniture tape wears out too quickly.

In most cases, the issue is not machine speed alone, but mismatch between tape structure and real operating conditions.

If the base structure lacks stability, the tape may stretch slightly over time.

If the surface design is not suitable for the tobacco type or forming pressure, friction performance can drop much earlier than expected.

In one export-oriented tobacco factory, Garniture tape had to be replaced every few months, causing frequent stoppages. After switching to a reinforced tape design with more stable surface behavior, replacement intervals were extended significantly and maintenance planning became much easier.

Garniture Tape and Suction Belts Work Together

Modern tobacco machines rely heavily on vacuum control.

Garniture tape rarely works alone — it must perform in harmony with suction belts and the vacuum system.

When Garniture tape friction is not balanced with suction parameters, operators may attempt to increase or decrease vacuum levels, often without lasting results. In many cases, the real issue lies in surface compatibility rather than machine settings.

For this reason, we usually recommend evaluating Garniture tape and suction belts as a matched system, especially when customers report unstable forming or increased waste during startup.

Practical Situations from the Field

In a recent machine upgrade project, a customer replaced both Garniture tape and suction belts at the same time. Before the change, startup scrap rates were high and adjustments took longer than expected. After installation and proper matching, cigarette forming stabilized quickly and startup losses were noticeably reduced.

Another customer supplying multiple international markets chose to standardize Garniture tape specifications across different machines. This decision simplified spare parts management and helped maintain consistent cigarette quality between production lines.

These are small changes on paper, but they have a clear impact on daily production efficiency.

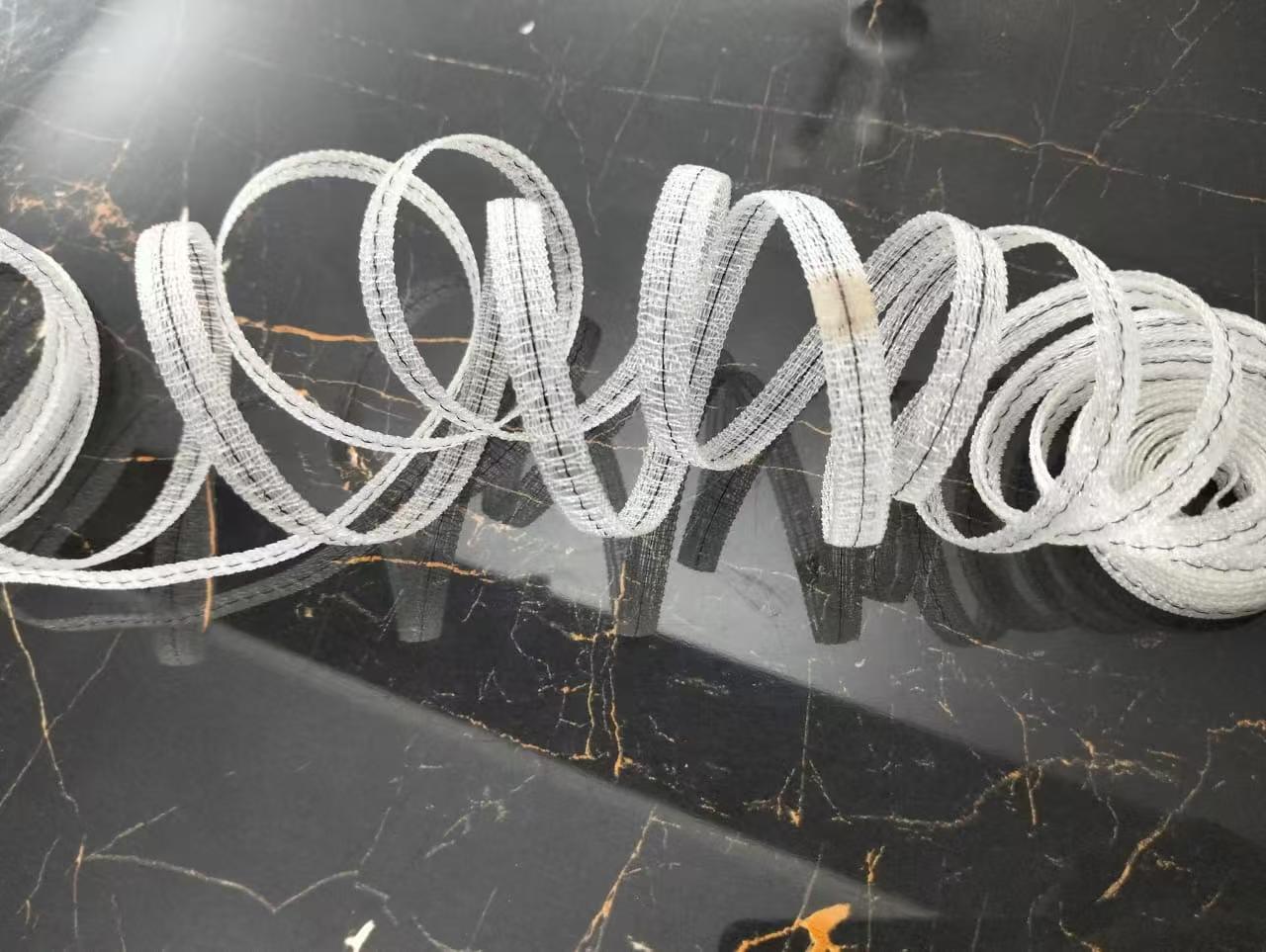

Typical Garniture Tape Characteristics

Garniture tape is usually manufactured from reinforced fabric or composite structures, with surface textures designed for controlled friction.

Width, thickness, and length are normally customized according to machine model and forming section design.

Endless construction, dimensional stability at high speed, and predictable wear behavior are often more important than theoretical material specifications.

Questions Customers Often Ask

Does Garniture tape directly affect cigarette quality?

Yes. It plays a direct role in rod forming consistency and visual appearance.

Can the same Garniture tape be used on different machines?

Not always. Even similar machines may require different surface or structural designs.

How often should Garniture tape be replaced?

There is no fixed cycle. Proper selection usually leads to longer and more predictable service life.

Can Garniture tape be supplied together with suction belts?

Yes. Many customers prefer to evaluate and replace both components together.

How Transovate Approaches Garniture Tape Projects

As an engineering-focused sub-brand of XZBelt, Transovate does not treat Garniture tape as a standard catalog item.

We focus on understanding machine type, operating speed, forming behavior, and maintenance feedback before recommending a solution.

Our goal is simple:

help customers reduce unnecessary stoppages, avoid repeated adjustments, and keep tobacco machines running smoothly over long production cycles.