In tobacco manufacturing, Suction Tape is often discussed together with Garniture tape, but in daily operation, its role is very different.

If Garniture tape shapes the cigarette rod, Suction Tape controls how tobacco is held, guided, and stabilized during high-speed forming.

Many customers contact us asking for Suction Tape as a replacement item.

However, once production issues are reviewed in detail, it becomes clear that Suction Tape selection has a direct impact on forming stability, startup losses, and long-term machine efficiency.

Why Suction Tape Is Critical in Tobacco Production

In modern cigarette machines, vacuum control plays a key role.

Suction Tape works together with the vacuum system to keep tobacco material precisely positioned during forming.

When Suction Tape does not perform as expected, operators often notice symptoms such as unstable rod formation, higher waste during startup, or difficulty maintaining consistent machine settings. These issues are sometimes mistaken for vacuum problems, while the real cause lies in Suction Tape surface condition or structure.

A properly selected Suction Tape provides stable suction behavior, allowing tobacco to remain evenly distributed and controlled throughout the forming process, even during long production runs.

Suction Tape Wear Is Often Misunderstood

One common misunderstanding is that Suction Tape wears quickly simply because machines run at high speed.

In reality, premature wear is usually linked to surface mismatch or structural instability, not speed alone.

If the surface of the Suction Tape becomes clogged, polished, or uneven, suction efficiency drops gradually. Operators may compensate by adjusting vacuum levels, but this rarely solves the problem for long.

We have seen cases where Suction Tape was replaced frequently without addressing the underlying issue. After switching to a more suitable Suction Tape design, replacement intervals increased noticeably and machine adjustments became less frequent.

Suction Tape and Garniture Tape Must Be Matched

In practical production, Suction Tape never works alone.

Its performance must be balanced with Garniture tape and the overall forming setup.

If Suction Tape suction force is too strong or too weak compared to Garniture tape friction, tobacco flow becomes unstable. This imbalance often shows up during machine startup or speed changes.

For this reason, many customers prefer to evaluate Suction Tape and Garniture tape together, rather than treating them as independent spare parts.

Practical Situations from the Field

In one high-speed cigarette production line, operators reported frequent instability during startup, even though machine settings were correct. After inspection, the Suction Tape surface showed uneven wear, reducing effective suction. Replacing the Suction Tape with a more stable surface design immediately improved startup behavior.

Another tobacco factory supplying multiple brands chose to standardize Suction Tape specifications across several machines. This reduced spare part variation and helped maintenance teams achieve more consistent results across different production lines.

These changes may seem small, but they have a measurable impact on daily production efficiency.

Typical Characteristics of Suction Tape

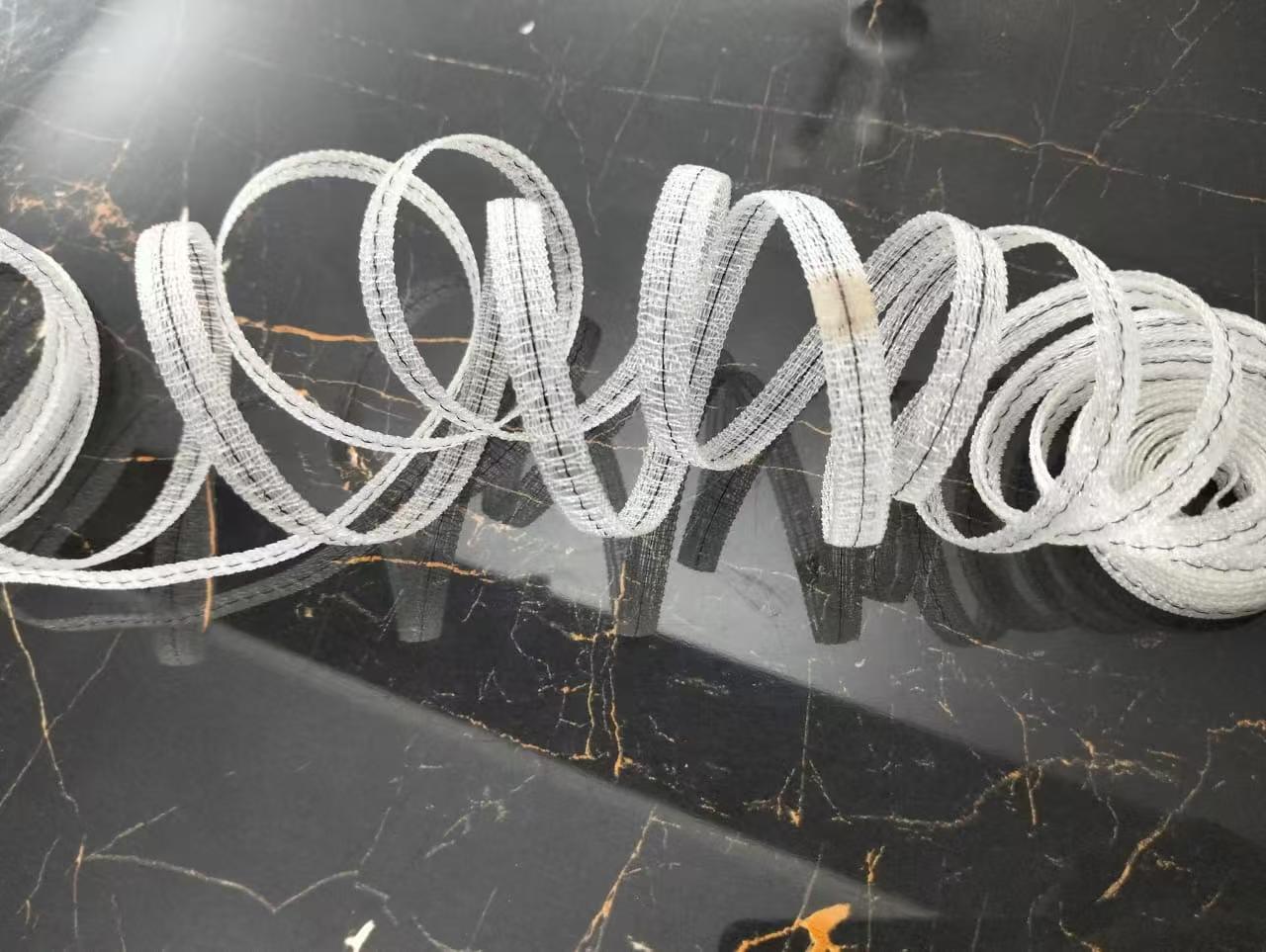

Suction Tape is usually manufactured from reinforced materials designed to maintain dimensional stability under continuous vacuum and mechanical stress.

Surface structure is engineered to support controlled airflow while resisting clogging from tobacco dust.

Width, thickness, hole pattern, and length are typically customized according to machine model and forming section design. In real operation, consistent behavior over time is more important than theoretical specifications.

Questions We Often Receive About Suction Tape

Does Suction Tape directly affect cigarette quality?

Yes. Stable suction helps ensure even tobacco distribution and consistent rod formation.

Can one Suction Tape design fit different machines?

Not always. Machine layout, speed, and vacuum configuration often require specific designs.

How often should Suction Tape be replaced?

There is no fixed interval. Correct selection usually leads to longer and more predictable service life.

Should Suction Tape be replaced together with Garniture tape?

In many cases, yes. Replacing both together often improves overall forming stability.

How Transovate Works with Suction Tape Projects

As an engineering-driven sub-brand of XZBelt, Transovate does not treat Suction Tape as a standard consumable.

We focus on understanding machine behavior, vacuum performance, operating speed, and customer feedback before recommending a solution.

Our objective is straightforward:

reduce unnecessary adjustments, minimize downtime, and help tobacco machines run smoothly over long production cycles.