Link V Belt Suppliers

Updated: 2025-11-5

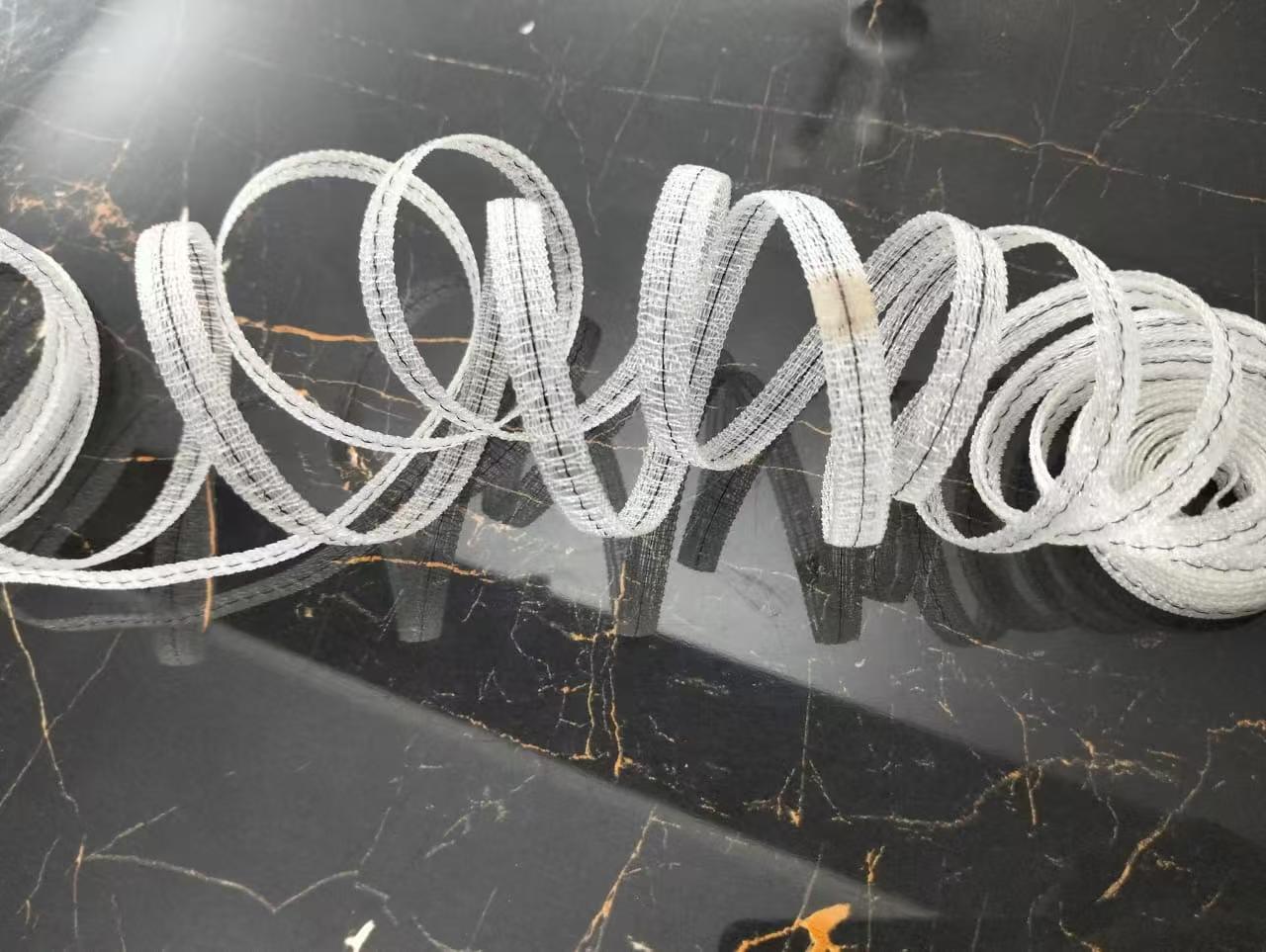

Unlike traditional endless V-belts, link V-belts are built from multiple modular segments (or “links”) that can be connected or removed to achieve the desired belt length. This innovative design provides excellent flexibility for on-site maintenance, quick replacement, and special industrial applications.

According to several industrial references, link belts offer robust construction, high flexibility, and reliable power transmission—making them ideal for variable-length drives or environments where downtime must be minimized.

Structurally speaking:

For Chinese manufacturers like XZBELT, adding link V-belts to your product range (alongside PU/PVC conveyor belts, timing belts, and roller drive belts) helps expand your reach in the global power transmission market.

Compared with traditional V-belts, link V-belts provide outstanding versatility, quick installation, and high adaptability—making them an ideal choice for industries requiring flexibility and reliability.

By leveraging XZBELT’s 20,000 m² factory, technical expertise, and patented belt technologies, your company is ready to offer global customers a complete, efficient, and innovative link V-belt solution—helping drive productivity and performance worldwide.

According to several industrial references, link belts offer robust construction, high flexibility, and reliable power transmission—making them ideal for variable-length drives or environments where downtime must be minimized.

Structurally speaking:

- Traditional V-belts are fixed-length continuous loops, delivering strong power transmission but limited adjustability.

- Link V-belts are made up of detachable segments that can be adjusted in length simply by adding or removing links.

- They are often made from polyurethane (PU) or polyester-reinforced materials, providing resistance to oil, water, and chemicals, and allowing use in extreme operating environments.

For Chinese manufacturers like XZBELT, adding link V-belts to your product range (alongside PU/PVC conveyor belts, timing belts, and roller drive belts) helps expand your reach in the global power transmission market.

Key Advantages and Applications

Advantages

- Adjustable Length & Easy Installation

- Link V-belts can be lengthened or shortened by changing the number of segments—no need to stock multiple fixed sizes. This makes them perfect for quick on-site repairs and reduces equipment downtime.

- Superior Environmental Resistance

- Many link V-belts are engineered to withstand exposure to oil, water, chemicals, and temperatures up to around 110 °C, maintaining performance even under extreme industrial conditions.

- Low Vibration and Smooth Operation

- The modular construction provides high flexibility and absorbs shock, helping the belt run more smoothly and quietly than conventional V-belts—especially on smaller pulley diameters or compact drive systems.

- Inventory Optimization

- Since link V-belts can be assembled to almost any required length, users and distributors can reduce the number of belt sizes they need to keep in stock.

Common Applications

- Machines with difficult or time-consuming maintenance requirements (e.g., lathes, milling machines, printing presses).

- Variable center distance drives or systems requiring frequent belt length changes.

- Harsh environments involving oil, moisture, dust, or chemicals.

- Production lines that demand minimal downtime and fast replacement.

Comparison: Link V-Belts vs. Traditional V-Belts

| Feature | Traditional V-Belt | Link V-Belt |

|---|---|---|

| Length | Fixed, endless loop | Modular, adjustable length |

| Maintenance | Full disassembly required | Quick on-site replacement |

| Environmental Resistance | Limited unless specially designed | High resistance to oil, heat, and chemicals |

| Power Transmission | Excellent for heavy-duty drives | Slightly lower efficiency, but better flexibility |

| Inventory | Many lengths needed | Fewer SKUs, flexible assembly |

How Chinese Manufacturers Can Position and Promote Link V-Belts

Product Positioning

- Highlight your 20,000 m² factory, 10+ patents, and professional R&D capabilities.

- Emphasize key advantages such as modular design, customizable length, quick on-site repair, and resistance to harsh environments.

- Position your brand as a cost-effective, reliable, and innovative Made-in-China supplier for global customers.

Marketing Recommendations

- Technical Documentation: Publish datasheets or white papers showcasing performance data and benefits like shorter downtime, reduced vibration, and improved environmental resistance.

- Sample Promotion: Offer trial samples or demo installations for key industries such as metalworking, printing, and logistics to demonstrate ease of installation and durability.

- Brand Differentiation: Market XZBELT as an expert in modular transmission solutions—backed by patents, advanced facilities, and consistent export experience.

- Export Focus: Target regions like Europe, Southeast Asia, and the Middle East, emphasizing flexibility, reliability, and fast customization.

- After-Sales Support: Provide belt selection guidance, inventory optimization consulting, and installation training to build trust with overseas clients.

Common Customer Pain Points & Solutions

| Customer Issue | XZBELT Solution |

|---|---|

| Long maintenance time and production downtime | Modular link design allows on-site replacement in minutes |

| Too many belt sizes in stock | Adjustable belt length reduces SKU count and storage cost |

| Harsh working environments (oil, water, chemicals, heat) | Durable PU/polyester construction resists wear and contamination |

| High noise and vibration | Flexible structure ensures smooth, quiet operation |

Conclusion

As a professional Chinese link V-belt manufacturer and supplier, XZBELT can deliver a new generation of modular, adjustable, and maintenance-friendly power transmission belts.Compared with traditional V-belts, link V-belts provide outstanding versatility, quick installation, and high adaptability—making them an ideal choice for industries requiring flexibility and reliability.

By leveraging XZBELT’s 20,000 m² factory, technical expertise, and patented belt technologies, your company is ready to offer global customers a complete, efficient, and innovative link V-belt solution—helping drive productivity and performance worldwide.