It is against this backdrop that Xuanze Industrial, with its independently developed patented product - the SIBR-5M Silicone timing Belt with silicone, has sparked a technological revolution in the production lines of hygiene products, breaking the foreign monopoly and elevating the overall level of the industry.

I. Xuanze Industrial: Innovation Leading the Future

Since its establishment in 2013, Xuanze Industrial has adhered to the core development concept of "independent development and innovation-driven" and is committed to becoming a leader in the field of industrial belts. The company has gathered a group of elite talents within the industry and, through relentless efforts, has successfully developed multiple patents with independent intellectual property rights, laying a solid foundation for the sustainable development of the enterprise. In September 2019, Xuanze Industrial was officially recognized as a "Shanghai High-Tech Enterprise," which is not only an acknowledgment of the company's technological innovation capabilities but also a recognition of its future development potential. At the same time, the company has passed ISO 9001 quality system certification and ISO 14001 environmental system certification, further proving its outstanding performance in quality management and environmental protection.

II. SIBR-5M Synchrous Belt with Silicone: A New Choice for Hygiene Product Production

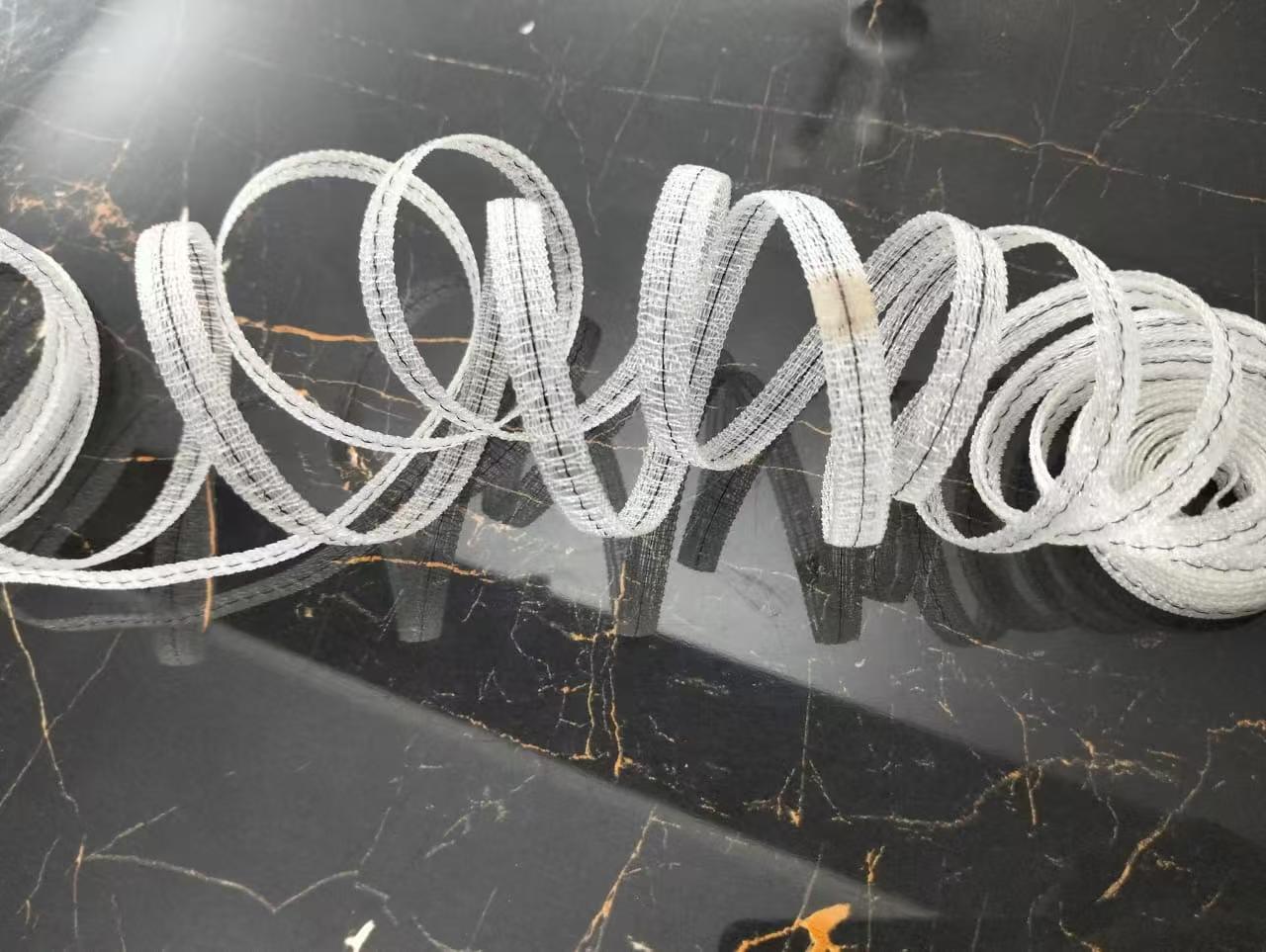

To meet the specific needs of the hygiene product industry, Xuanze Industrial independently developed the SIBR-5M synchronous belt with silicone, an innovative product. This product combines the non-stick and high-temperature resistant properties of silicone material with the precise transmission advantages of synchronous belts, making it particularly suitable for production lines of sanitary pads, diapers, pull-up pants, adult incontinence pads, and more. Its unique design allows for operating speeds of up to 1200-1400 RPM, greatly improving production efficiency. At the same time, the bonding strength between the silicone and the synchronous belt is extremely high, effectively preventing cracking and debris shedding, ensuring the cleanliness and safety of the production process.

III. Breaking the Monopoly, Surpassing Imported Quality

For a long time, foreign brands like Japan's NITTA have dominated the high-end belt market in the hygiene product industry. However, Xuanze Industrial's SIBR-5M synchronous belt with silicone has successfully broken this monopoly with its excellent performance. The company's products surpass imported counterparts in terms of wear resistance, tensile strength, and visual inspection accuracy, while offering a more reasonable price. In rigorous testing at Shanghai Unicharm's factory, our belt lasted for over six months, far exceeding the three-month lifespan of imported products, fully demonstrating its superior performance and quality.

IV. Ample Inventory, Quick Response to Customer Needs

To meet customers' urgent needs, Xuanze Industrial always maintains ample inventory. Whether it's standard specifications or custom products, we can complete production and delivery to customers in a short amount of time. In addition, the company is equipped with advanced production equipment and precision testing instruments to ensure that every batch of products meets high-standard quality requirements.

V. Continuous Innovation, Creating a Glorious Future Together

Facing the future, Xuanze Industrial will continue to adhere to the path of independent innovation, constantly researching new products and technologies to meet the ever-changing market demands. We will adopt a more open mindset to communicate and cooperate with domestic and foreign peers, jointly promoting technological progress and development in the hygiene product industry. At the same time, we look forward to collaborating with more partners to create a more glorious future together!

Model

Surface Coating

Base Belt

Temperature Range

Application Environment and Advantages

SIBRTIMING

SI Silicone

Rubber Timing Belt

-20-160°C

Suitable for high-speed hygiene product machines, with speeds up to 1000-1500 pieces/min, can be used for glue spouts and flat conveyance

SIPUTIMING

SI Silicone

PU Timing Belt

-20-200°C

Suitable for high-speed hygiene product machines, with speeds up to 1000-1500 pieces/min, can be used for glue spouts and flat conveyance

Silicone synchronous belts are widely used in various industries due to their excellent performance. Below are some of the main application areas:

- Food Processing Industry: In the cleaning, cutting, and packaging stages of food production, silicone synchronous belts play a crucial role. Their one-piece molded design ensures hygiene and safety during use, while also meeting FDA and UFDA standards. They are non-stick and easy to clean, ensuring that food remains uncontaminated1234.

- Pharmaceutical Industry: The production and packaging of pharmaceuticals require materials that are both safe and wear-resistant. Silicone synchronous belts are not only wear-resistant and heat-resistant but also ensure that pharmaceuticals are not contaminated during production, improving efficiency and reducing maintenance costs1.

- Sanitary Products Industry: In the production lines for sanitary pads, diapers, pull-up pants, and adult incontinence pads, silicone synchronous belts are the ideal choice due to their non-stick, heat-resistant properties, high operating speeds (up to 1200-1400 RPM), and strong bonding strength with no cracking or debris shedding. They have broken the monopoly of foreign brands in this field and have improved the technological level of domestic production lines for sanitary products5.

- High-Temperature Working Environments: Silicone synchronous belts can be used for extended periods in high-temperature environments up to 200°C, making them particularly suitable for synchronous belt applications that require operation at high temperatures. Their excellent heat resistance, ozone resistance, chemical corrosion resistance, and good electrical insulation properties make them stand out in high-temperature and corrosive environments34.

The advantages of silicone synchronous belts in the production lines of hygiene products are significant, as they not only enhance production efficiency but also ensure product quality and the safety of the production environment. The following are the main advantages of silicone synchronous belts:

1. Non-Stick and Easy to Clean

- Low Surface Energy: Silicone material has extremely low surface energy, making its surface less likely to adhere to materials or dirt, reducing the need for cleaning during the production process.

- Ease of Cleaning: Even if there is a small amount of residue, the silicone surface is easy to clean, maintaining the hygienic condition of the production line and meeting the high standards required for the production of hygiene products.

2. High Temperature and Low Temperature Resistance

- Wide Temperature Range Adaptability: Silicone synchronous belts can work stably under extreme temperature conditions, such as -20°C to 200°C (depending on the model), adapting to various production environments.

- Thermal Stability: In high-temperature environments, silicone material is less prone to deformation or aging, ensuring the stability and reliability of the transmission system.

3. Wear Resistance and Durability

- High Abrasion Resistance: Silicone material has excellent abrasion resistance, capable of withstanding wear over long periods of operation, thus extending its service life.

- Tear Resistance: Silicone synchronous belts have good tear resistance, maintaining integrity even under high loads or sudden impacts.

4. Precision Transmission and Stability

- Synchronization: Silicone synchronous belts, when used in conjunction with synchronous wheels, can achieve precise transmission ratios, ensuring synchronization during the production process.

- Stability: The elasticity and toughness of silicone material keep the synchronous belt stable during operation, reducing vibration and noise, and improving the quality of production.

5. Environmental Protection and Safety

- Non-Toxic and Odorless: Silicone material is non-toxic and odorless, meeting food-grade and medical-grade standards, and will not contaminate hygiene products.

- Flame Retardancy: Some silicone synchronous belts have flame-retardant properties, enhancing the safety of the production environment.

6. Wide Application and Flexibility

- Suitable for Multiple Scenarios: Silicone synchronous belts are not only suitable for the production lines of hygiene products but are also widely used in industries such as food, pharmaceuticals, and packaging.

- Customization Services: According to customer needs, silicone synchronous belts can be customized in terms of length, width, tooth profile, etc., to meet the demands of different production lines.

7. Cost Reduction and Efficiency Improvement

- Reduced Maintenance Costs: Due to the wear resistance, durability, and ease of cleaning of silicone synchronous belts, the maintenance frequency and costs of the production line are reduced.

- Improved Production Efficiency: Precision transmission and stable operation improve production efficiency, reducing downtime and defect rates.