Conveyor belts are one of the most widely used pieces of equipment in industrial production. From mining and logistics to manufacturing and food processing, they play a vital role in ensuring continuous and efficient material handling. However, many companies face a common challenge during operation: conveyor belt slippage.

This problem not only reduces production efficiency but also increases energy consumption, accelerates equipment wear, and poses potential safety risks. How can manufacturers and operators effectively address conveyor belt slippage?

As a professional China conveyor belt manufacturer, headquartered in Shanghai with a factory in Huzhou, Zhejiang—Xuanze Industrial Drive Systems (Shanghai) Co., Ltd., we provide a comprehensive analysis of the causes of conveyor belt slippage and practical solutions for B2B buyers.

Common Causes of Conveyor Belt Slippage

Before implementing solutions, it’s essential to identify the root causes. The main reasons include:

- Insufficient tension

- If the conveyor belt is not tensioned correctly, it becomes slack, resulting in low friction between the belt and pulley, which leads to slippage.

- High moisture or powder materials

- Materials with high water content or fine powder may penetrate the belt’s backside or pulley surface, reducing adequate friction.

- Pulley design limitations

- A smooth or poorly designed pulley surface may not provide sufficient friction for reliable operation.

- Heavy load operation

- Excessive belt weight or transported material load can exceed the available friction, leading to slippage.

- System design flaws

- Inadequate scraper systems, ineffective cleaning devices, poor tensioning systems, or mismatched power designs may also trigger slippage.

Other external factors, such as humidity changes, dust, and steep conveying angles, should also be considered when diagnosing the issue.

The Negative Impact of Conveyor Belt Slippage

If not solved promptly, conveyor belt slippage can cause multiple adverse effects:

- Reduced productivity – Decreased conveying efficiency slows down the entire production line.

- Increased energy consumption – Motors run longer under strain, consuming more power.

- Accelerated wear and tear – Continuous slippage damages both the conveyor belt and pulleys.

- Higher operational costs – Frequent repairs and downtime affect profitability.

- Safety hazards – Severe slippage may lead to belt breakage or sudden stops, posing a risk to workers.

That’s why implementing an effective conveyor belt slippage solution is critical for every industrial operation.

Solutions to Conveyor Belt Slippage

As a professional Shanghai conveyor belt supplier and Zhejiang conveyor belt factory, we recommend the following proven methods:

1. Professional Belt Selection

Choosing the right belt material and structure is the first step. For example:

- For humid environments → select belts with higher friction coefficients.

- For heavy-duty applications → choose stronger belts with reinforced tension members.

At Xuanze Industrial Drive Systems, we provide one-on-one technical support to ensure correct belt selection for each application.

2. Regular Inspection and Maintenance

Daily monitoring helps prevent minor issues from turning into major problems:

- Check material moisture levels to avoid excessive slip.

- Ensure that cleaning devices, such as scrapers and brushes, are functioning correctly.

- Monitor belt tension and alignment to prevent slack and mis-tracking.

3. Improve Tensioning Systems

Automatic or adjustable tensioning systems can dynamically maintain the right friction force between the belt and pulley.

4. Pulley Surface Optimization

Applying pulley lagging (rubber coating) or patterned surfaces increases friction and prevents belt slippage.

5. Power System Matching

Ensure the motor and drive system are correctly matched with the conveyor load. Undersized motors often contribute to slippage problems.

6. Customized Engineering Solutions

Each industry has unique requirements. As an experienced China conveyor belt manufacturer, we provide tailor-made conveyor belt solutions for various industries, including mining, logistics, electronics, food, and automotive parts.

Why Choose Xuanze Industrial Drive Systems?

- Professional Manufacturer in China – Headquartered in Shanghai with a factory in Huzhou, Zhejiang.

- B2B-Focused Solutions – We understand the key concerns of global buyers: reliability, cost-efficiency, and after-sales support.

- Technical Expertise – Decades of conveyor belt manufacturing experience with strong R&D capabilities.

- Global Service – Our products are exported to Southeast Asia, Europe, and other regions.

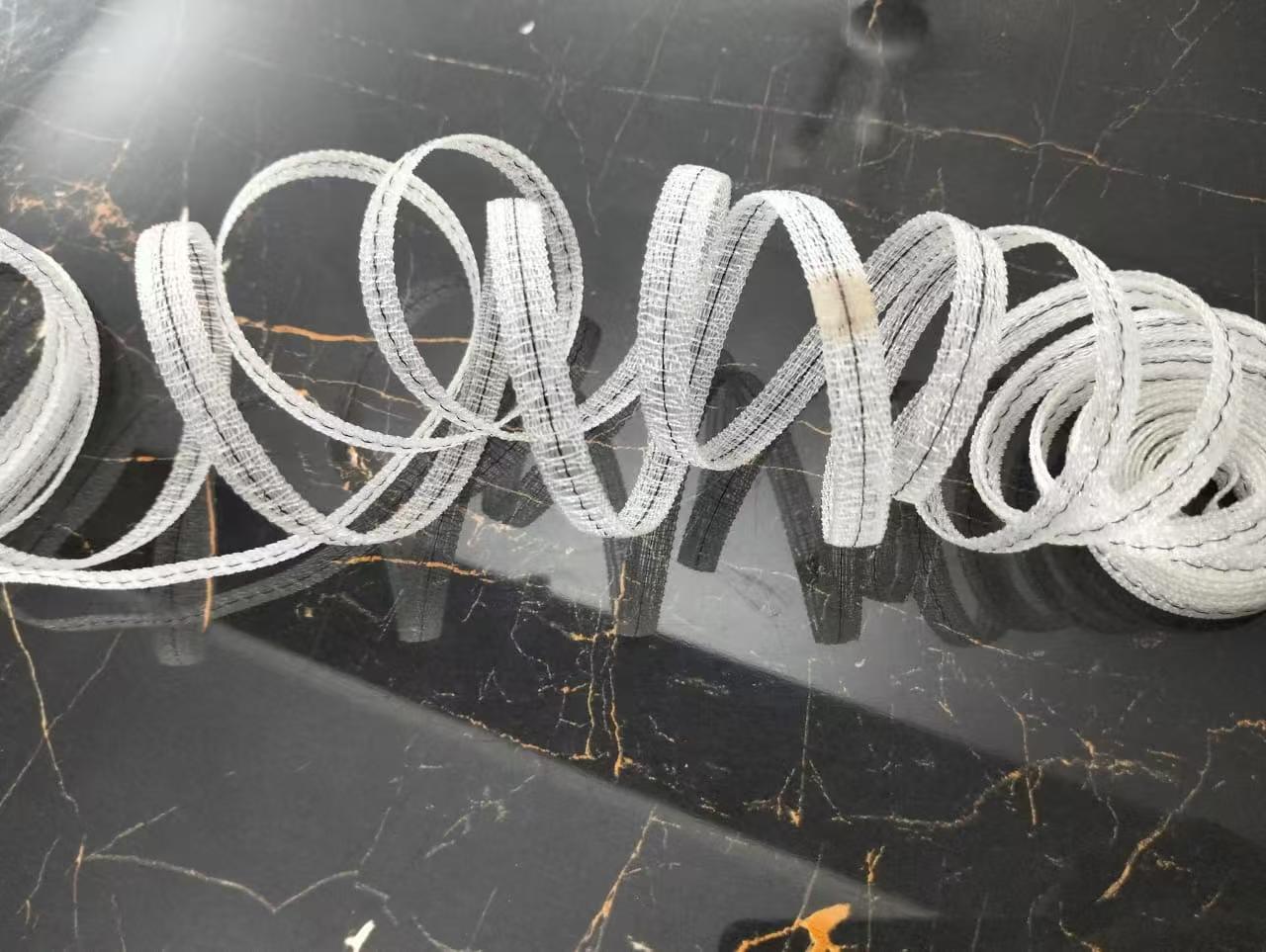

- Comprehensive Product Range – Including PVC conveyor belts, PU conveyor belts, patterned belts, cotton belts, and more.

Conclusion

Conveyor belt slippage is a common but solvable issue in industrial operations. By understanding the root causes—such as insufficient tension, high moisture materials, or system design flaws—and applying practical solutions, businesses can significantly improve efficiency, reduce costs, and ensure safe production.

As a trusted China conveyor belt manufacturer, Xuanze Industrial Drive Systems (Shanghai) Co., Ltd. is committed to providing global buyers with high-quality conveyor belts and customized solutions. Whether you operate in the CNC, electronics, automotive parts, or food processing industries, we can deliver reliable products and engineering support to help your business thrive.