Powertwist Common Models and Applications

Updated: 2025-9-29

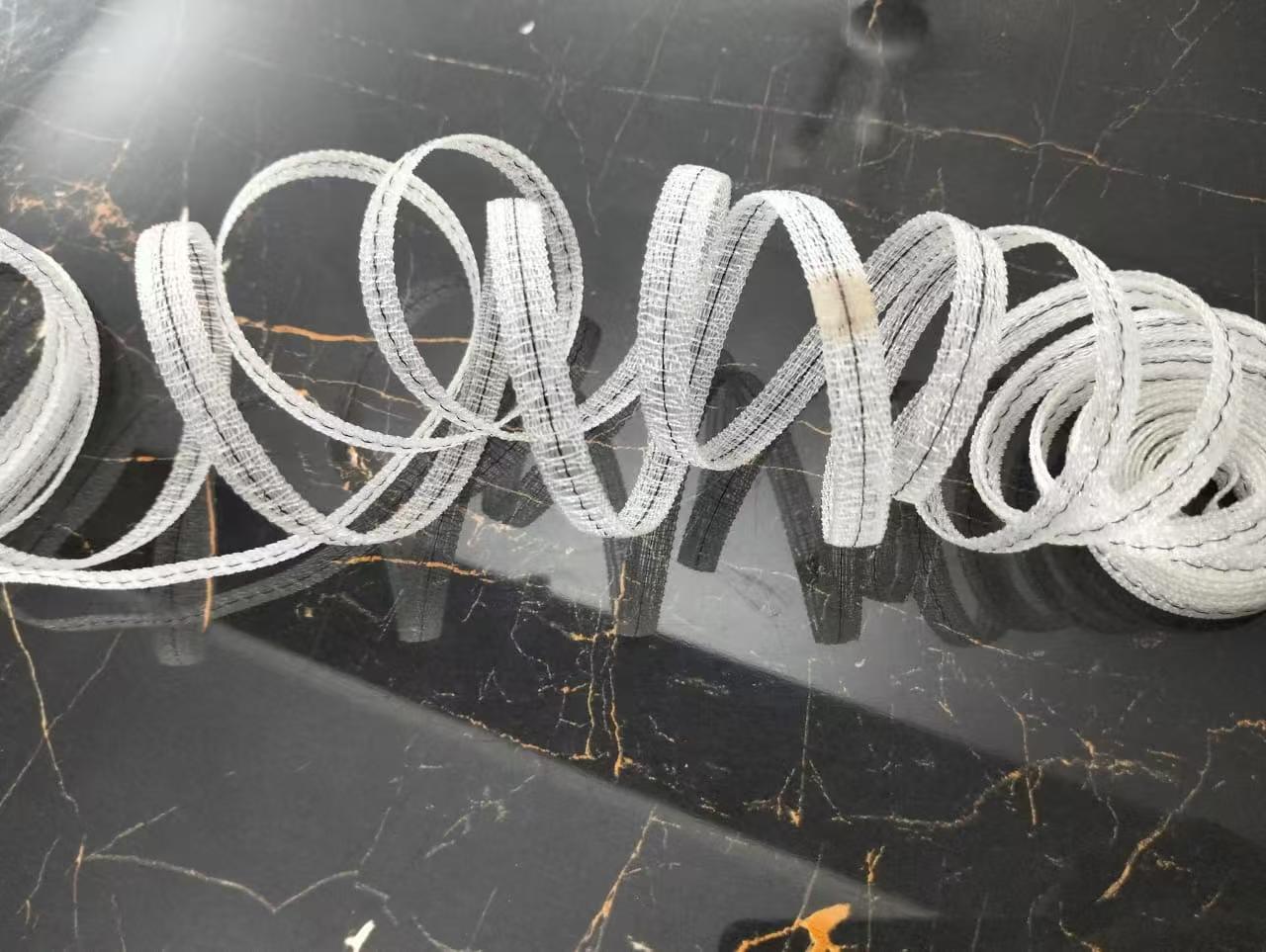

Powertwist definition

Powertwist is a high-performance, detachable link belt made from a polyurethane and polyester composite material. It is widely used in industrial transmission and conveying applications. It features quick tool-free splicing, wear and oil resistance, high tensile strength, and is a viable alternative to traditional rubber V-belts.

Why Choose Powertwist?

In daily production, when drive belts wear or break, replacing traditional V-belts often requires significant downtime and can also delay production due to the unavailability of the appropriate specifications. The Powertwist link belt's most crucial advantage is its "ready-to-use" design. Operators can manually splice the links to the desired length without specialized tools, allowing immediate operation.

Powertwist's high-strength polyurethane and polyester materials provide excellent wear and oil resistance, ensuring stable performance in high-humidity and high-temperature environments. This means Powertwist drive belts provide long-lasting reliability in sawmills, fans, compressors, and a variety of industrial machinery.

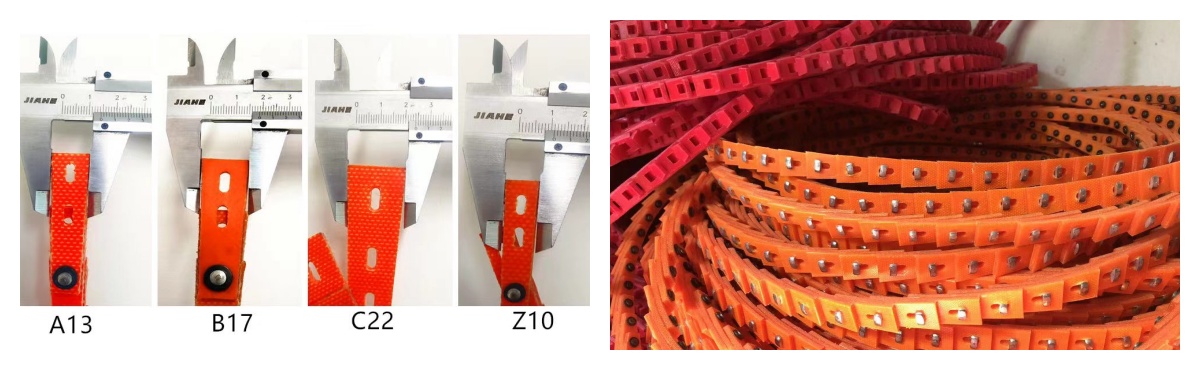

Powertwist Common Model Comparison Table

How do I choose the right Powertwist belt size?

To select Powertwist belt sizes, confirm the groove type, diameter, and operating power of your existing equipment's pulleys. The Powertwist series aligns perfectly with traditional V-belt specifications, such as A/13 and B/17, making it easy to find a corresponding replacement.

Even if an exact match isn't in stock, you can quickly adjust the length by cutting or splicing, ensuring immediate operation.

This means your equipment no longer needs to be down waiting for a special belt specification, ensuring continuous production.

Powertwist's high-strength polyurethane and polyester materials provide excellent wear and oil resistance, ensuring stable performance in high-humidity and high-temperature environments. This means Powertwist drive belts provide long-lasting reliability in sawmills, fans, compressors, and a variety of industrial machinery.

Powertwist Common Model Comparison Table

| Traditional V-Belt Model | Equivalent Powertwist Model | Common Size (Section Width) | Typical Applications |

|---|---|---|---|

| 3L | Powertwist 3L | ~ 9.5 mm | Small woodworking machines, light-duty fans |

| 4L / A | Powertwist A / A+ | ~ 13 mm | Woodworking machines, fans, compressors, lathes |

| 5L / B | Powertwist B / B+ | ~ 17 mm | HVAC fans, high-power pumps, conveyors |

| C | Powertwist C / C+ | ~ 22 mm | Mining machines, heavy-duty conveyors, mixers |

| D | Powertwist D / D+ | ~ 32 mm | Steel plants, heavy-duty drives, metallurgical equipment |

| Poly V-belt replacement | Powertwist Drive Belt | Flexible splice length | Long-distance drives, noise reduction systems |

| Emergency maintenance needs | Powertwist Link Belt | Adjustable to any length | On-site quick replacement of traditional V-belts |

How do I choose the right Powertwist belt size?

To select Powertwist belt sizes, confirm the groove type, diameter, and operating power of your existing equipment's pulleys. The Powertwist series aligns perfectly with traditional V-belt specifications, such as A/13 and B/17, making it easy to find a corresponding replacement.

Even if an exact match isn't in stock, you can quickly adjust the length by cutting or splicing, ensuring immediate operation.

This means your equipment no longer needs to be down waiting for a special belt specification, ensuring continuous production.