Truly Endless Belt: The Power and Precision Choice in the Metalworking Industry

In the field of metalworking, every detail is crucial to production efficiency, product quality, and cost control. And the truly endless belt, as a key component in this industry, is leading the transformation and development of the industry with its unique advantages.

I. The Unique Charm of Truly Endless Belt

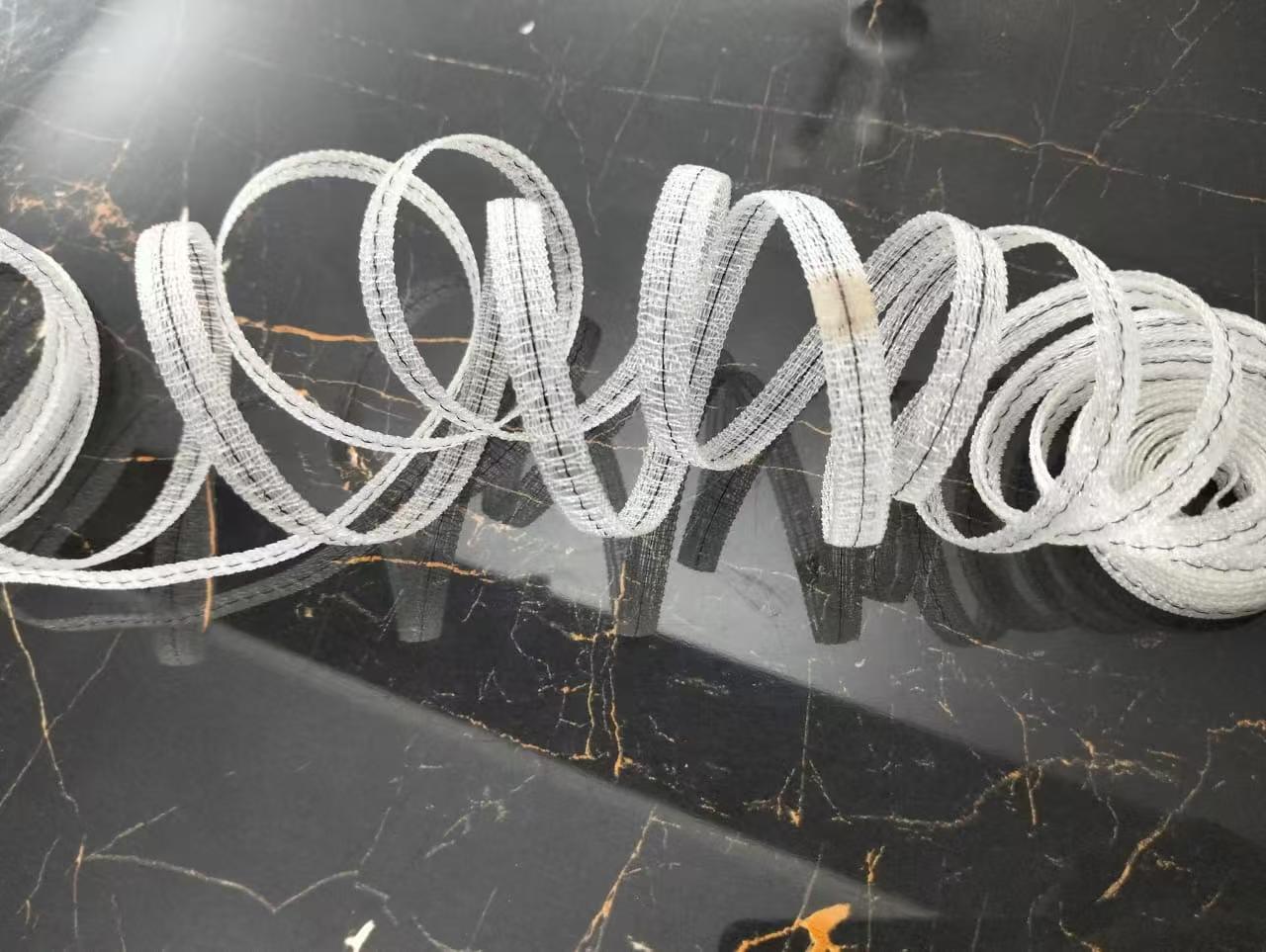

1. The Superiority of Seamless Design

Compared with traditional belts, the biggest highlight of the truly endless belt lies in its seamless design. This feature eliminates many problems caused by joints in traditional belts, such as uneven wear at the joints, signal transmission interruption, and unstable power transmission. In metalworking, whether it's a fast-spinning machine or a precise conveyor, a seamless belt helps everything run smoothly and without interruption. This makes the production process more reliable and steady. For example, in high-speed stamping equipment, the seamless belt can withstand frequent impact forces and high speeds, ensuring the consistency of the accuracy and strength of each stamping, thus improving the stability of product quality.

2. High Precision and High Performance Coexist

Metalworking often requires extremely high precision, and the truly endless belt meets this demand perfectly. Its manufacturing process is exquisite, achieving high dimensional accuracy and surface quality, ensuring that there will be no shaking, deviation, and other phenomena in the process of transmission and conveying, thus guaranteeing the high precision of metalworking. At the same time, this belt has excellent strength and wear-resistant performance, being able to operate stably for a long time in harsh working environments, bearing large loads and friction forces, effectively extending the service life, reducing the maintenance cost and downtime of equipment, and bringing significant economic benefits to metalworking enterprises.

3. Wide Adaptability

The metalworking industry covers many different processes and application scenarios, such as cutting, grinding, polishing, stamping, etc., and each process has different requirements for belts. Relying on its excellent performance and flexible design, the truly endless belt can adapt to various complex working environments and diverse application needs. Whether in high-temperature, high-humidity environments, or in places with corrosive media, it can maintain good performance. In addition, by selecting appropriate materials and structures, the seamless belt can also meet the requirements of different speeds and power transmission, providing customized solutions for various metalworking equipment.

II. Key Applications in the Metalworking Industry

1. Efficient Power Source for Transmission Systems

In metalworking equipment, the transmission system is one of the core components, and its performance directly affects the operation efficiency and machining quality of the entire equipment. As an important part of the transmission system, the truly endless belt can realize efficient and precise power transmission. For example, in the spindle transmission of CNC machines, the seamless belt transmits the rotation movement of the motor smoothly to the spindle, ensuring the accuracy and stability of the machine at high speeds. Compared with traditional transmission methods, seamless belt transmission has higher transmission efficiency, lower noise, and vibration levels, which can effectively reduce energy consumption and equipment wear and tear, and improve the overall performance and service life of the machine.

2. Reliable Guarantee for Conveying Devices

In the process of metalworking, it is often necessary to transport raw materials, semi-finished products, or finished products between different processes, which requires reliable conveying devices. With its seamless design and good flexibility, the truly endless belt has become an ideal choice for conveying devices. In automated production lines, the seamless belt can accurately convey materials to each processing station according to the predetermined trajectory and speed, realizing an efficient production process. For example, in the production line of automotive parts machining, the seamless belt conveying system can quickly and smoothly transport engine blocks, crankshafts, and other parts between various processes, ensuring the continuity and rhythm of production, greatly improving production efficiency.

3. Accurate Assistance in Special Machining Processes

In addition to traditional transmission and conveying applications, the truly endless belt also plays an important role in some special metal machining processes. For example, in the continuous stamping forming process of metal sheets, the seamless belt can provide uniform pressure and stable support, ensuring the forming accuracy and surface quality of the sheet during stamping. In the polishing treatment of metal surfaces, the seamless belt can drive the polishing wheel to rotate at high speed, realizing the fine polishing of the metal surface, making the product surface reach a very high level of glossiness and flatness. These applications fully demonstrate the versatility and irreplaceability of the truly endless belt in the metalworking industry.

III. How to Choose a Suitable Truly Endless Belt

1. Determine Parameters According to Application Scenarios

When choosing a truly endless belt, first of all, we need to fully consider the specific application scenarios of metalworking. If it is a high-load, high-speed transmission system, such as the spindle transmission of large CNC machines, it is necessary to choose a belt with higher strength, wear resistance, and fatigue resistance, and pay attention to its maximum allowable speed and power transmission capacity. For conveying devices, the width, thickness, and carrying capacity of the belt should be determined according to the weight, size, and conveying distance of the conveying material. In special machining processes, we also need to choose the seamless belt with corresponding performance characteristics according to the process requirements, such as pressure, temperature, accuracy, etc.

2. Pay Attention to Material Quality and Manufacturing Process

Material quality and manufacturing process directly affect the performance and service life of the truly endless belt. High-quality materials can provide better strength, wear resistance, and corrosion resistance, while advanced manufacturing processes can ensure the dimensional accuracy, surface quality, and structural stability of the belt. Therefore, when choosing a seamless belt, we should choose manufacturers with a good reputation and professional experience, understand the source of their materials, production processes, and quality control systems. At the same time, we can refer to the evaluations and actual use cases of other users to comprehensively evaluate different brands and models of seamless belts.

3. Consider Installation and Maintenance Convenience

Correct installation and regular maintenance are crucial for the performance and life of the truly endless belt. When choosing a belt, we need to consider the difficulty of its installation, whether it can perfectly match the existing equipment, and whether it needs special installation tools and techniques. In addition, we should also pay attention to the maintenance requirements of the belt, such as lubrication method, cleaning method, replacement cycle, etc. Choosing a seamless belt that is easy to install and maintain can reduce equipment downtime and maintenance costs, and improve production efficiency.

Version

Color

Rubber*

Tensile Core

Application

Abrasion Resistance

Thermal Resistance

Oil Resistance on the top surface

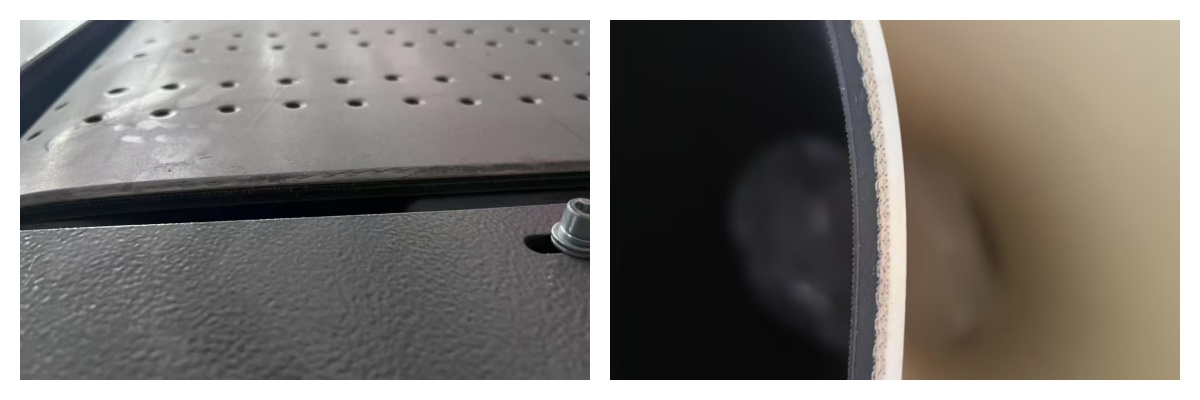

XZBELT-01

black

Nitrile Neoprene

TED100

Dry

●

●

●●

XZBELT-02

black

Nitrile Neoprene

TEMB0

Wet

●

●

●●

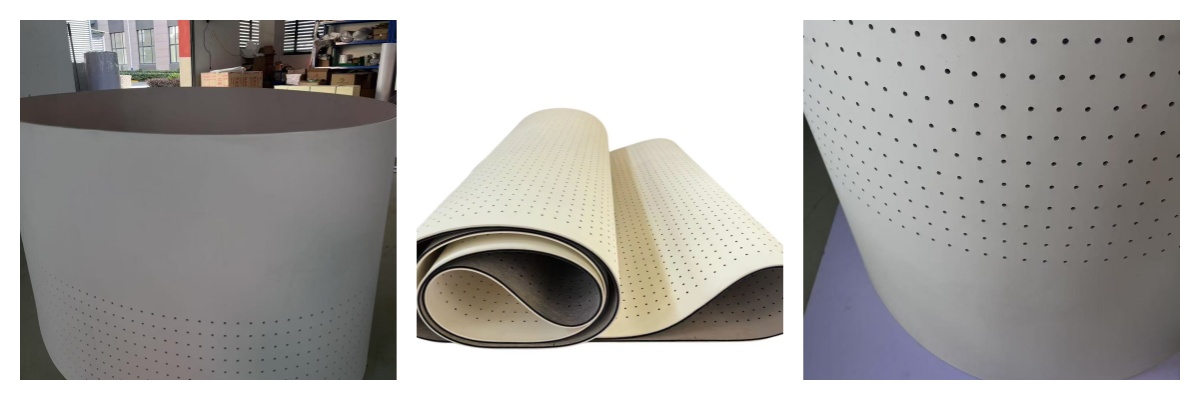

XZBELT-03

white

Nitrile Neoprene

TED100

Dry

●●

●

●●

XZBELT-04

white

Nitrile Neoprene

TEMB0

Wet

●●

●

●●

XZBELT-05

white

Hypalon

TED100

Dry

●●●

●●

●

XZBELT-06

white

Hypalon

TEMB0

Wet

●●●

●●

●

IV. Future Development Trends and Prospects

With the continuous development of the metalworking industry and the continuous progress of technology, the truly endless belt is also constantly innovating and improving. In the future, we can expect it to make greater breakthroughs in the following aspects:

1. Material Innovation

The research and development of new materials will bring more excellent performance to the truly endless belt. For example, high-strength, lightweight composite materials are expected to be applied in the manufacture of seamless belts, making them lighter while improving strength and wear resistance, reducing the energy consumption and operating costs of equipment. In addition, intelligent materials with self-lubrication, self-healing, and other functions will also become a key direction of research, further improving the service life and reliability of seamless belts.

2. Intelligent Applications

With the promotion of Industry 4.0, the metalworking industry is developing towards intelligence. The truly endless belt will also be combined with sensor technology, Internet of Things technology, etc., to realize intelligent monitoring and management. Through real-time monitoring of the operating state, temperature, pressure, and other parameters of the belt, we can predict the faults and wear conditions of the belt in advance, and carry out maintenance and replacement in a timely manner, avoiding equipment downtime and production losses caused by belt faults. At the same time, the intelligent seamless belt can also automatically adjust operating parameters according to different machining tasks and process requirements, realizing more precise and efficient transmission and conveying.

3. Environmental Protection and Sustainable Development

In today's world, where environmental awareness is increasingly strong, the metalworking industry is also actively seeking more environmental-friendly and sustainable solutions. As a key transmission and conveying element, the truly endless belt will play a greater role in environmental protection. In the future, seamless belts will adopt more environmental-friendly materials and manufacturing processes to reduce pollution to the environment. At the same time, by improving the service life and recyclability of the belt, reducing the waste of resources, we can realize the green development of the metalworking industry.

In conclusion, as an important part of the metalworking industry, the truly endless belt provides a powerful guarantee for the efficient and stable operation of metalworking equipment with its seamless design, high precision, high performance, and wide adaptability. When choosing and applying the truly endless belt, we need to fully consider its characteristics and practical application needs, choose the appropriate product, and pay attention to installation and maintenance, so as to give full play to its advantages. Looking forward to the future, with the continuous innovation and development of technology, the truly endless belt will play a more important role in the metalworking industry, and make greater contributions to realizing the intelligent, efficient, and sustainable development of the metalworking industry.