Call Us: +86-13916946090

Inquiry Now

Hygienic, Reliable & Application-Driven Conveying for Food Processing

In the food industry, a conveyor belt is not just a moving surface.

It directly affectsfood safety, production efficiency, cleaning frequency, and equipment uptime.

From raw material handling to final packaging, every food processing step places different demands on the conveyor system. A belt that performs well in logistics or general manufacturing may fail quickly in a food environment.

XZBeltprovidesfood industry conveyor belt solutionsbased on real processing conditions, helping food manufacturers and equipment builders achieve stable, hygienic, and long-term operation.

Why Conveyor Belts Are Critical in the Food Industry

Food processors face a unique combination of challenges:

-

Direct or indirect food contact

-

Frequent washing and sanitation

-

Exposure to oil, fat, moisture, and cleaning chemicals

-

Soft, fragile, or sticky products

-

Long operating hours with minimal downtime

In these conditions, a poorly selected conveyor belt can quickly lead to contamination risks, product damage, excessive belt wear, and unplanned production stops.

Afood industry conveyor beltmust balancehygiene, durability, stability, and cleanabilityat the same time.

How XZBelt Approaches Food Processing Applications

AtXZBelt, conveyor belts for food processing are selectedby application, not by catalog.

Different food processes behave very differently on a conveyor:

-

Raw meat vs cooked products

-

Dough vs packaged goods

-

Wet environments vs dry lines

-

Manual handling vs fully automated systems

XZBelt engineers focus on how the product moves, where contamination risks exist, and how the belt behaves after months of cleaning and continuous operation. This application-driven approach allows XZBelt to recommendfood processing conveyor beltsthat perform reliably beyond initial installation.

Food Industry Applications Supported by XZBelt

Meat & Sausage Processing

Meat and sausage production lines operate inhigh-moisture, oily environments, often with direct food contact.

Common challenges include slipping, deformation, and strict hygiene requirements.

Typical XZBelt solutions include:

-

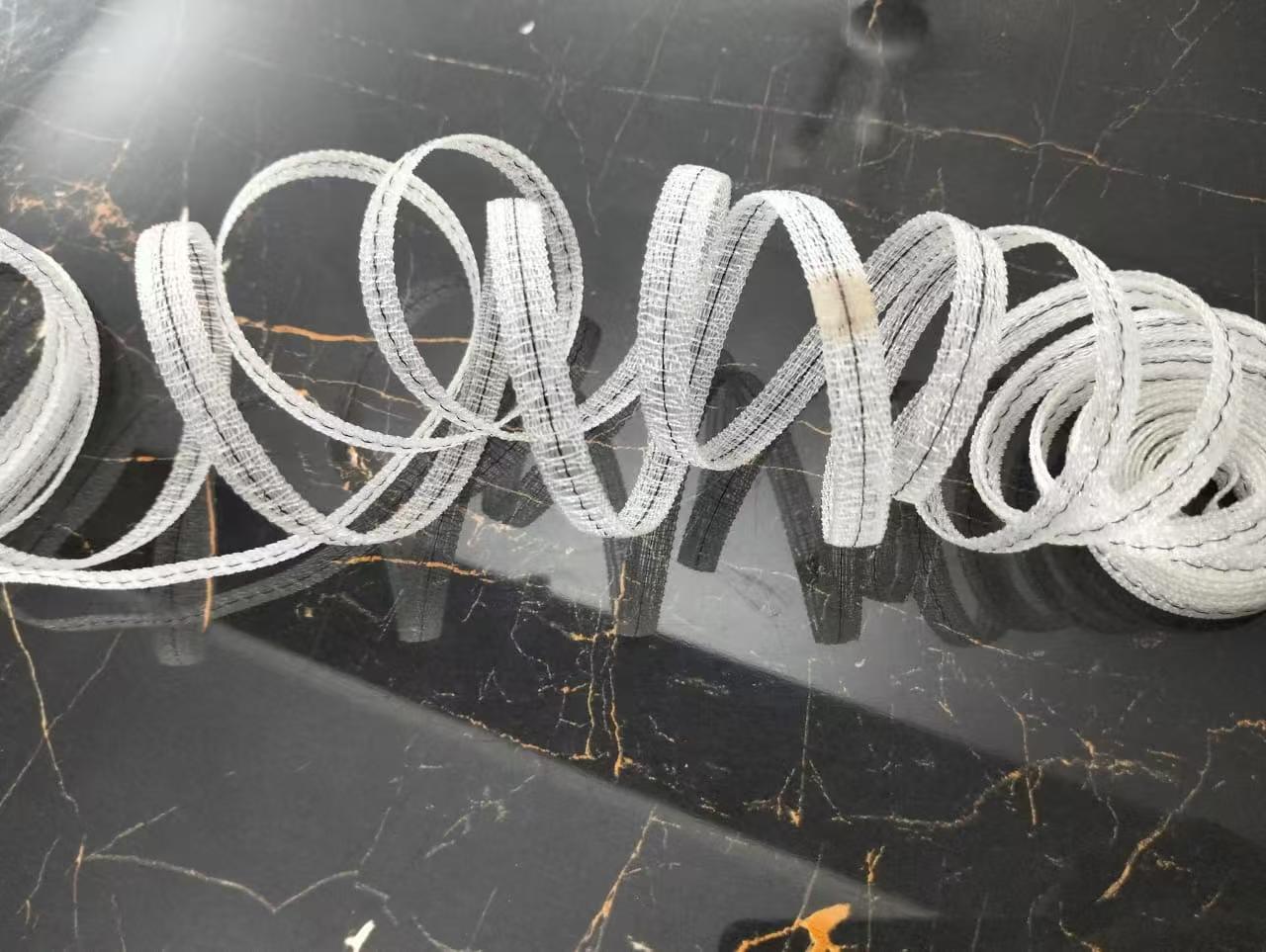

Food-grade PU conveyor belts

-

Timing belts for sausage linking and cutting machines

-

Easy-clean, non-absorbent belt surfaces

-

Stable tracking under continuous operation

These solutions help maintain consistent portioning and reduce contamination risks.

Bakery & Dough Handling

Bakery products introduce challenges such as dough sticking, high temperatures near ovens, and soft product deformation.

XZBelt conveyor belt solutions focus on:

-

Non-stick food-grade surfaces

-

Heat-resistant materials

-

Gentle conveying to protect product shape

-

Stable belt behavior at varying speeds

Proper belt selection can significantly reduce dough loss and cleaning time.

Seafood & Frozen Food Processing

Seafood and frozen food lines operate incold, wet, and corrosive environments.

XZBelt supports these applications with:

-

Low-temperature flexible conveyor belts

-

Moisture- and salt-resistant constructions

-

Smooth surfaces that prevent residue buildup

Fruit, Vegetable & Fresh Produce Handling

Fresh produce is easily bruised and damaged during conveying.

Key requirements addressed by XZBelt include:

-

Soft contact belt surfaces

-

Stable movement without sudden speed changes

-

Frequent washdown capability

These conveyor belt solutions prioritize product protection and hygiene.

Food Packaging & End-of-Line Automation

At the packaging stage, precision becomes critical.

XZBelt provides solutions for:

-

Accurate positioning for sealing, labeling, and cutting

-

High-speed continuous operation

-

Long daily running hours

Timing belts and stable conveyor belts are commonly used to ensure reliable positioning and throughput.

What Makes a Conveyor Belt Truly Food-Grade

At XZBelt, a food-grade conveyor belt is defined bylong-term performance, not labels alone.

Key considerations include:

-

Non-toxic, non-absorbent materials

-

Smooth or controlled-texture surfaces

-

Resistance to oil, moisture, and cleaning agents

-

No fiber shedding or surface cracking

-

Long-term dimensional stability

The goal is to ensure the belt remains safe and functional after months or years of real food processing operation.

Custom Conveyor Belt Solutions for Food Processing Lines

Food processing equipment is rarely standardized.

XZBelt supports customized conveyor belt solutions, including:

-

Custom belt width, length, and thickness

-

Endless or jointed belt designs

-

Cleats, guides, and profiles

-

Replacement for existing branded belts

-

OEM and maintenance support

Customization allows conveyor belts to integrate into existing machines without redesigning equipment.

Why Food Industry Customers Choose XZBelt

Food industry customers chooseXZBeltbecause of:

-

Application-driven belt selection

-

Experience across multiple food sectors

-

Ability to supply original and alternative belt solutions

-

Stable quality and predictable delivery

-

Engineering support beyond product supply

In food processing, belt failure is not just a maintenance issue — it is a production risk.

Frequently Asked Questions (FAQ)

Can XZBelt conveyor belts be used for direct food contact?

Yes. Food-grade conveyor belts are available for direct and indirect food contact applications.

How often do food conveyor belts require cleaning?

Cleaning frequency depends on the product and process. XZBelt belt surfaces are designed to simplify sanitation.

Can XZBelt replace belts from other brands?

Yes. Replacement solutions are commonly provided based on drawings or samples.

Do you support trial orders?

Yes. Trial orders are available to verify performance before full-scale use.

Talk to XZBelt About Your Food Processing Application

Every food product behaves differently on a conveyor.

TellXZBeltwhat you are processing, how your line operates, and where problems occur.

The rightfood industry conveyor belt solutionstarts with understanding the application.