In today’s manufacturing landscape—especially in glassware and metal heat-processing industries—production systems face multiple challenges, including high temperatures, heavy loads, wear, and the need for uninterrupted operation. As a vital part of the production line, conveyor belts must offer exceptional heat resistance, structural stability, and product protection.

Traditional metal mesh belts, while heat-resistant, come with significant drawbacks such as thermal shock, product scratching, and high energy consumption. To address these issues, xzbelt has independently developed a series of Kevlar® high-temperature conveyor belts, specifically designed to meet the needs of high-temperature transportation in glass products, aluminum profiles, and metal parts processing.

Call Us: +86-13916946090

Inquiry Now

In today’s manufacturing landscape—especially in glassware and metal heat-processing industries—production systems face multiple challenges, including high temperatures, heavy loads, wear, and the need for uninterrupted operation. As a vital part of the production line, conveyor belts must offer exceptional heat resistance, structural stability, and product protection.

Traditional metal mesh belts, while heat-resistant, come with significant drawbacks such as thermal shock, product scratching, and high energy consumption. To address these issues, xzbelt has independently developed a series of Kevlar® high-temperature conveyor belts, specifically designed to meet the needs of high-temperature transportation in glass products, aluminum profiles, and metal parts processing.

Why Choose Kevlar Belts?

In the production of glassware, the stage between pressing and annealing is particularly prone to product damage.When hot glass hits cold, rigid steel mesh belts, it can easily crack, break, or get scratched—leading to a lot of wasted products.

But Kevlar belts? They’ve got a bunch of big advantages that make a real difference.

1. Superior Heat Resistance

xzbelt’s Kevlar belts are made with Kevlar aramid fiber, stainless steel fiber, PBO, and PBI, providing instant heat resistance up to 760°C and continuous operation at up to 690°C—ideal for transporting hot glass, metal components, or extruded aluminum profiles.

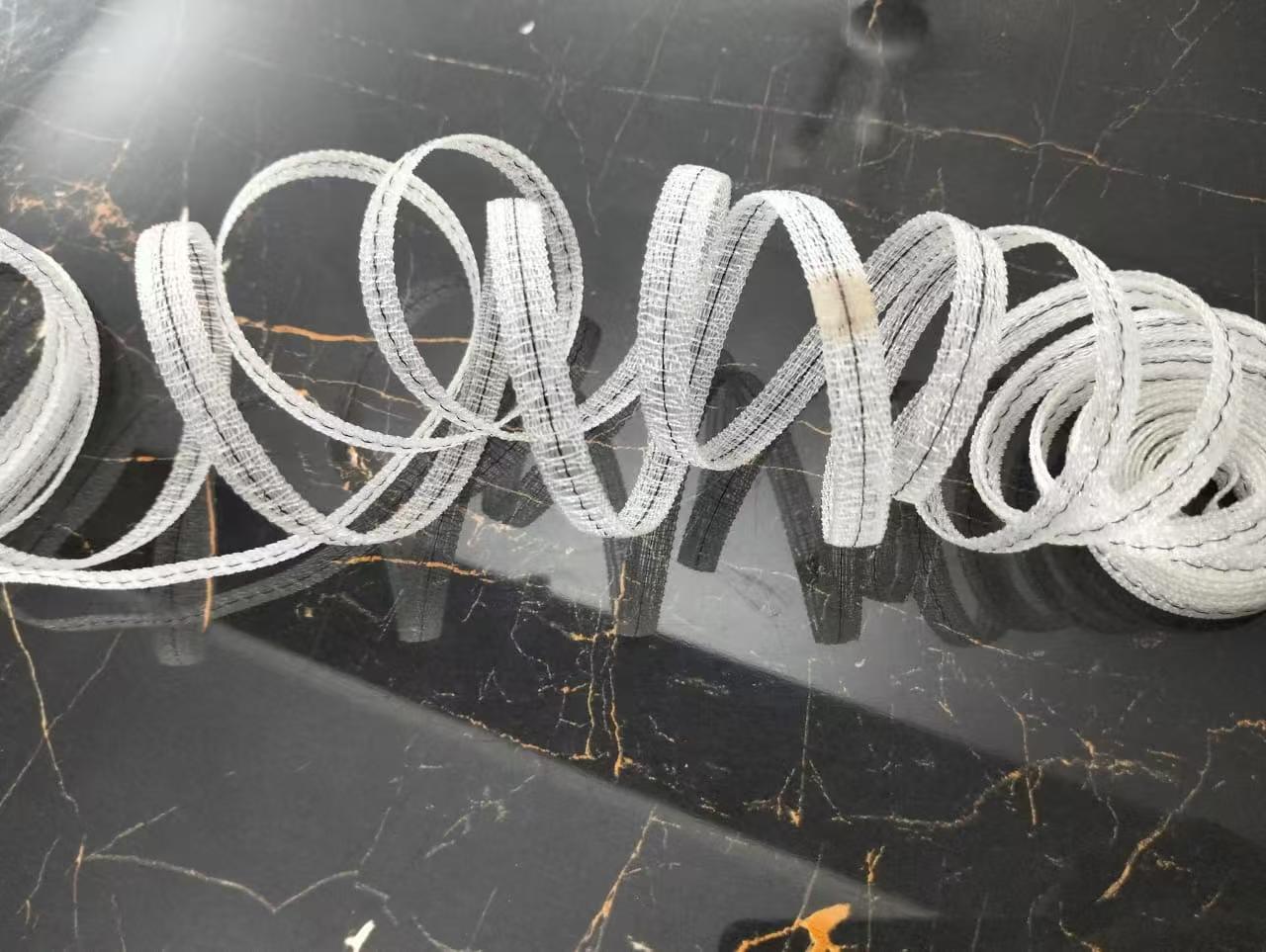

2. Dense, Multi-Layer Weaving Structure

These belts are made with a thick, tightly woven multi-layer design, usually between 7mm and 9mm thick. They come in common widths like 300mm, 400mm, 500mm, and 610mm. This makes them really tough, super strong, and long-lasting—even when things get tough.

3. Soft Surface, Scratch-Free Transport

The Kevlar surface is smooth, lint-free, and gentle on delicate products. Even at high temperatures, it will not scratch glass or aluminum items, making it ideal for high-end or precision product lines.

4. Energy-Saving and Eco-Friendly

Kevlar belts work without needing any extra heaters, so they save energy and cut down on emissions. That means they help you go green and keep your running costs low.

5. Easy Installation and Customizable

Belts can be fitted with steel fasteners for quick on-site installation, and are compatible with various machine types. xzbelt also provides optional features like perforation, anti-wear coatings, or anti-static treatment based on customer needs.

Parameter Category

Detailed Specifications/Description

Brand

xzbelt

Product Name

Kevlar® High-Temperature Conveyor Belt (Aramid Heat-Resistant Belt)

Thickness

Standard: 7mm, 8mm, 9mm

Customizable: Other thicknesses available upon request

Width

Standard: 300mm, 400mm, 500mm, 610mm

Customizable: Other widths available upon request

Material Composition

Kevlar® aramid fiber, PBO, PBI, stainless steel yarn, and other high-temperature composite materials

Weaving Structure

Multi-layer high-density woven construction

Operating Temperature

Continuous: ≤690°C

Peak (instant): ≤760°C

Tensile Strength

≥1800N/25mm (varies by belt width)

Elongation at Break

<3% (maintains belt shape stability)

Abrasion Resistance

≥5000 cycles (DIN abrasion test standard)

Anti-Scratch Surface

Soft fiber surface, non-marking and non-shedding

Tear Resistance

Excellent (suitable for heavy-duty, continuous operation)

Joint Options

Standard: Steel mechanical fasteners

Optional: Thermal splicing

Application Sections

Annealing furnace inlet, hot-forming output, cooling sections, aluminum extrusion lines, ceramic kilns

Target Industries

Glassware, aluminum profiles, metal forging, ceramics, baking/food processing

Optional Features

Wear-resistant coating, perforations, anti-static layer

Key Advantages

Heat-resistant, flexible, non-marking, lint-free, energy-saving, eco-friendly

Available Colors

Yellow (Kevlar natural) or Black (with surface coating)

Standards Compliance

xzbelt internal quality standard (ref. ISO 21182, DIN 22102)

Minimum Order Quantity

1 unit (sample orders accepted)

Packaging

Moisture-proof PE wrap + corrugated box + export wooden crate (reinforced options available)

Lead Time

In-stock for standard sizes; 3–7 days for customization

Customizable: Other thicknesses available upon request

Customizable: Other widths available upon request

Peak (instant): ≤760°C

Optional: Thermal splicing

Target Industries & Applications

Glass Industry

- Applications: Drinking glasses, ovenware, lamp glass, appliance glass panels, and more.

- Key Stage: From forming machines to annealing furnace entry.

- Benefits: Prevents thermal shock and cracking, increases product yield and safety.

Aluminum Extrusion

- Applications: Aluminum window frames, heat sinks, structural profiles.

- Key Stage: Hot aluminum profile cooling and transition stages.

- Benefits: Avoids surface scratches and deformation of high-temperature aluminum products.

Metal Heat Processing

- Applications: Metal forging, heat treatment transfer lines, die-casting output.

- Benefits: Resists extreme temperatures and mechanical stress over continuous operation.

Ceramics & Food Baking Lines

- Suitable for ceramic kilns, industrial dryers, or food ovens where both high temperatures and clean handling are required.

Why xzbelt?

- Top-Grade Materials: We use only high-performance fibers like Kevlar, PBO, and stainless steel yarns to ensure long-lasting belt integrity.

- In-House Manufacturing: All belts are made in our factory with strict quality control, certified to ISO standards. OEM/ODM available.

- Global Logistics: Standard sizes are in stock and ready to ship within 24 hours. Full export documents and English installation guides are available.

- Full Technical Support: From model selection and customization to on-site jointing assistance, we offer full-service solutions for international clients.

Conclusion

As factories aim for smarter, greener, and more automated production, Kevlar high-temperature conveyor belts are quickly becoming the go-to upgrade from old-school metal mesh belts. Built to handle extreme heat and heavy use, they help protect your products, cut down on costs, and boost efficiency.

At xzbelt, we’re all about helping global manufacturers get the right belt for the job. Whether you're making glassware, aluminum profiles, or heat-treated metal parts, we've got heat-resistant conveyor belts you can count on.

📩 Need a sample, quote, or more info? Get in touch with xzbelt today — we’ll help you level up your production line with belts that are smarter, tougher, and safer.