Call Us: +86-13916946090

Inquiry Now- Production Factory

- High Quality

- Good Price

- OEM/ODM

I. Product Definition & Core Value

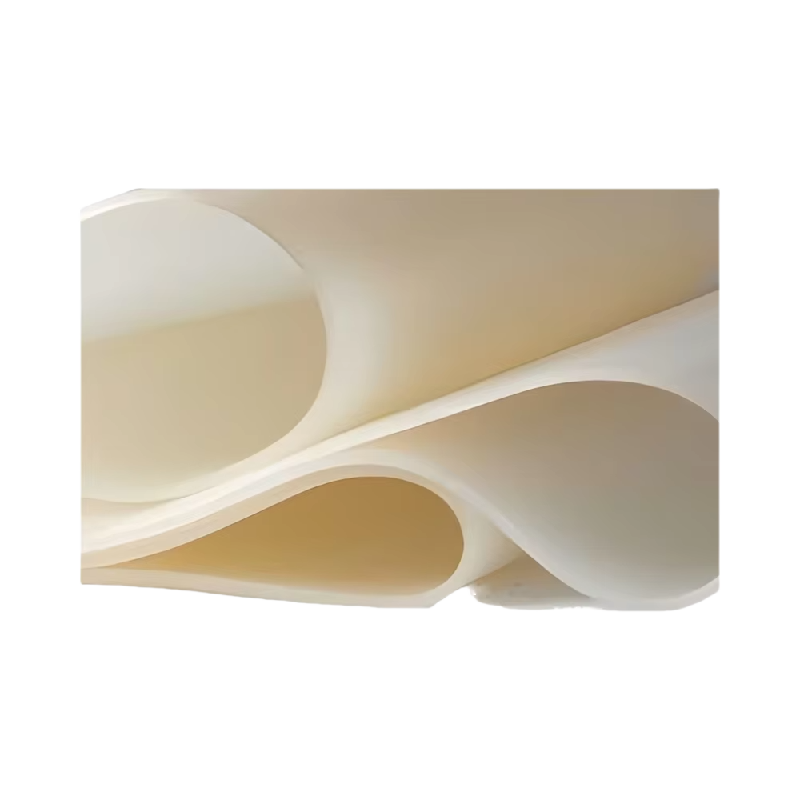

Our silicone conveyor belts are manufactured from high-purity platinum-catalyzed silicone rubber compounds using precision extrusion molding technology, specifically designed for high-cleanliness environments, extreme temperature conditions, and high-precision transmission requirements. Unlike ordinary rubber belts, their molecular structure provides exceptional thermal stability, bioinertness, and electrical insulation properties, making them widely applicable in premium manufacturing sectors such as food pharmaceuticals, new energy batteries, and semiconductor wafer production. Each belt undergoes laser calibration ensuring straightness error <0.3mm/m to meet millimeter-level positioning demands of automated production lines.

II.Key Technical Specifications Table

| Parameter | Standard Specification | Special Working Conditions Options | Testing Method |

|---|---|---|---|

| Max Belt Width | 200mm / 400mm / 600mm | Customizable up to 1200mm | DIN ISO 5295 |

| Thickness Range | 1.5mm~8mm | Ultra-thin version 0.8mm (for precision instrument internal drive) | IPCE ultrasonic thickness gauge |

| Tensile Strength | ≥8MPa | High-strength grade up to 15MPa | GB/T 528-2009 |

| Hardness Grade | Shore A 50±5 | Adjustable from Shore A 30~80 based on application needs | ISO 7619 Shore hardness tester |

| Min Driven Roller Diameter | Φ30mm | Micro version supports Φ15mm driver roller | FEM simulation verification |

| Ozone Aging Resistance | Dynamic testing ≥200 hours | Reinforced version up to 500 hours | ASTM D1149 accelerated aging test |

| Antimicrobial Property | ISO 22196 antibacterial rate >99.9% | Medical-grade silver ion loaded version achieving >99.99% | JIS Z 2801 quantitative detection |

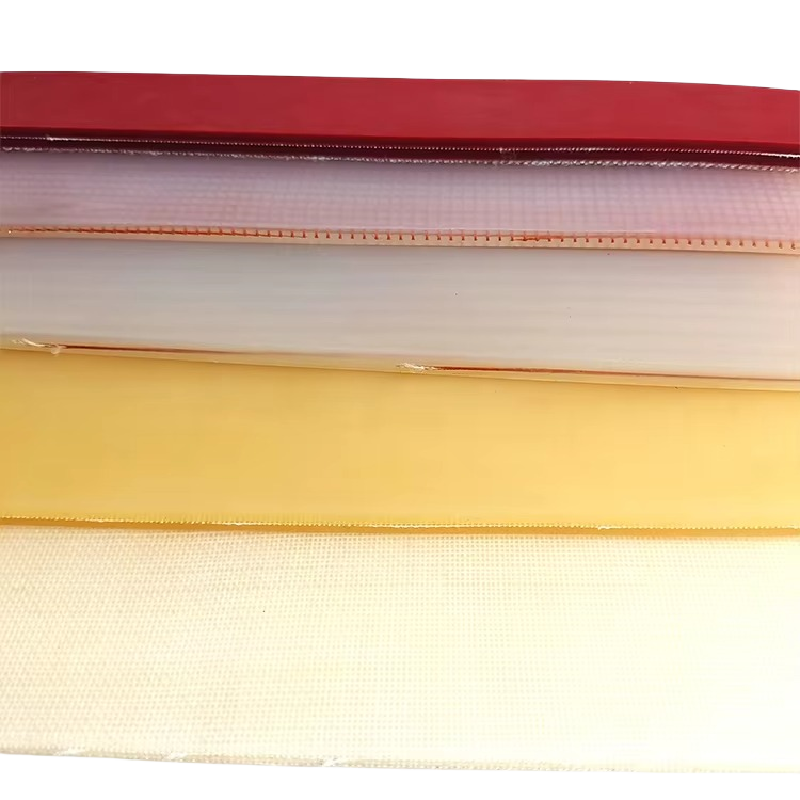

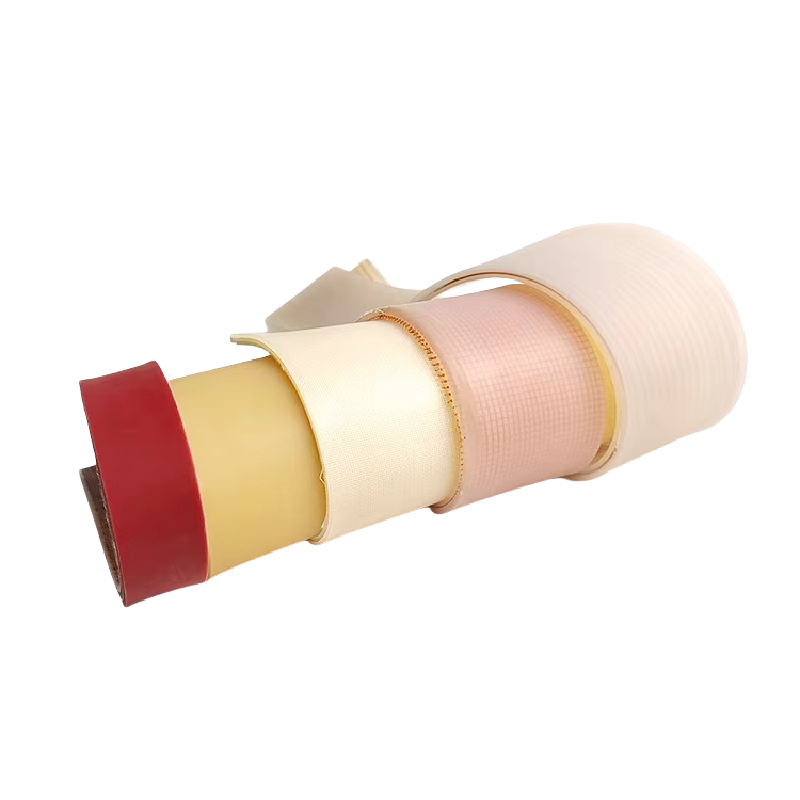

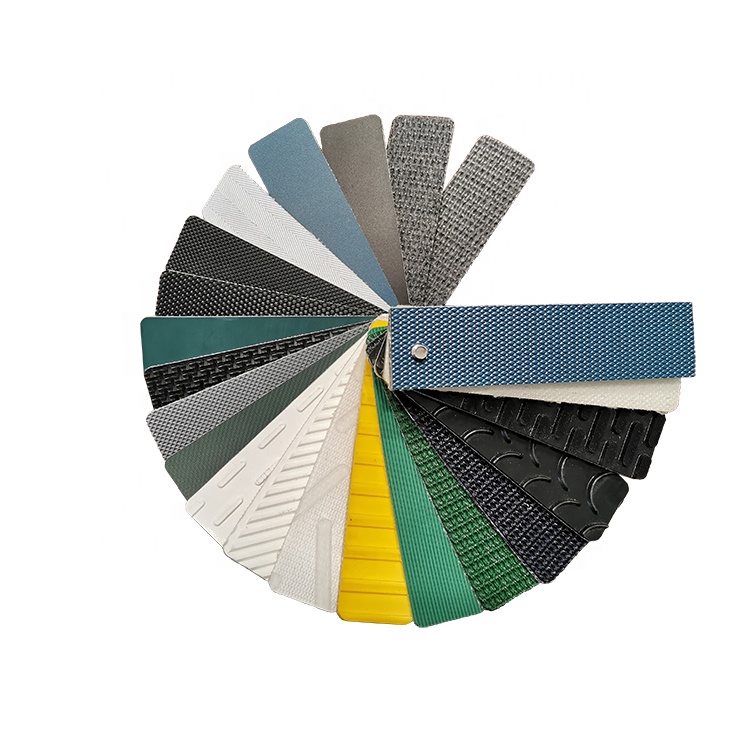

| Color Options | Natural/White/Blue | Custom Pantone color matching (requires additional lead time) | RAL color code comparison system |

1. Ultra-Wide Temperature Adaptability

✅ Operational temperature range from -60℃ to +300℃, with instantaneous heat resistance up to 350°C, suitable for extreme conditions like liquid nitrogen freezing and high-temperature sterilization.

▶️ Application Value: Eliminates frequent belt changes due to temperature variations; a single belt supports multiple processes including freeze-drying, baking, and melting.

2. Food & Pharmaceutical Grade Safety Certification

✔️ Passes FDA/LFGB/GB food contact material tests with extractable substance migration below 0.01mg/kg, compliant with EU RASFF strict standards.

▶️ Industry Breakthrough: The only conveyor solution certified under both ISO 9001 Quality Management System and ISO 13485 Medical Device Quality System.

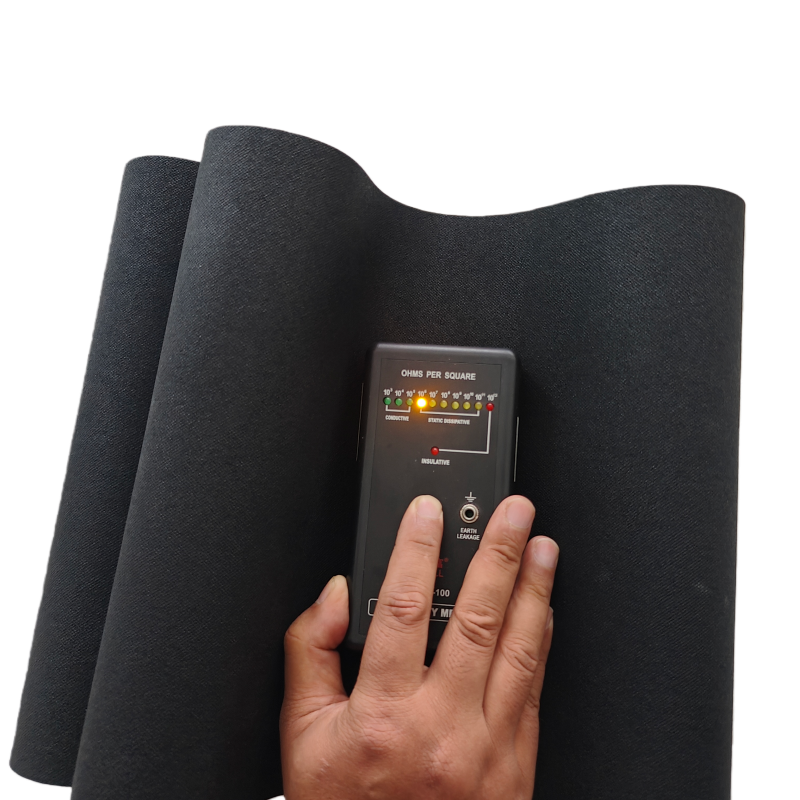

3. Intelligent ESD Protection System

🔍 Maintains stable surface resistivity between 10⁶~10⁹Ω, featuring embedded carbon black conductive layers for bidirectional static discharge.

▶️ Efficiency Gains: Reduces defect rates in electronic component assembly lines and minimizes maintenance frequency caused by dust adhesion on precision instruments.

4. Exceptional Durability Innovation

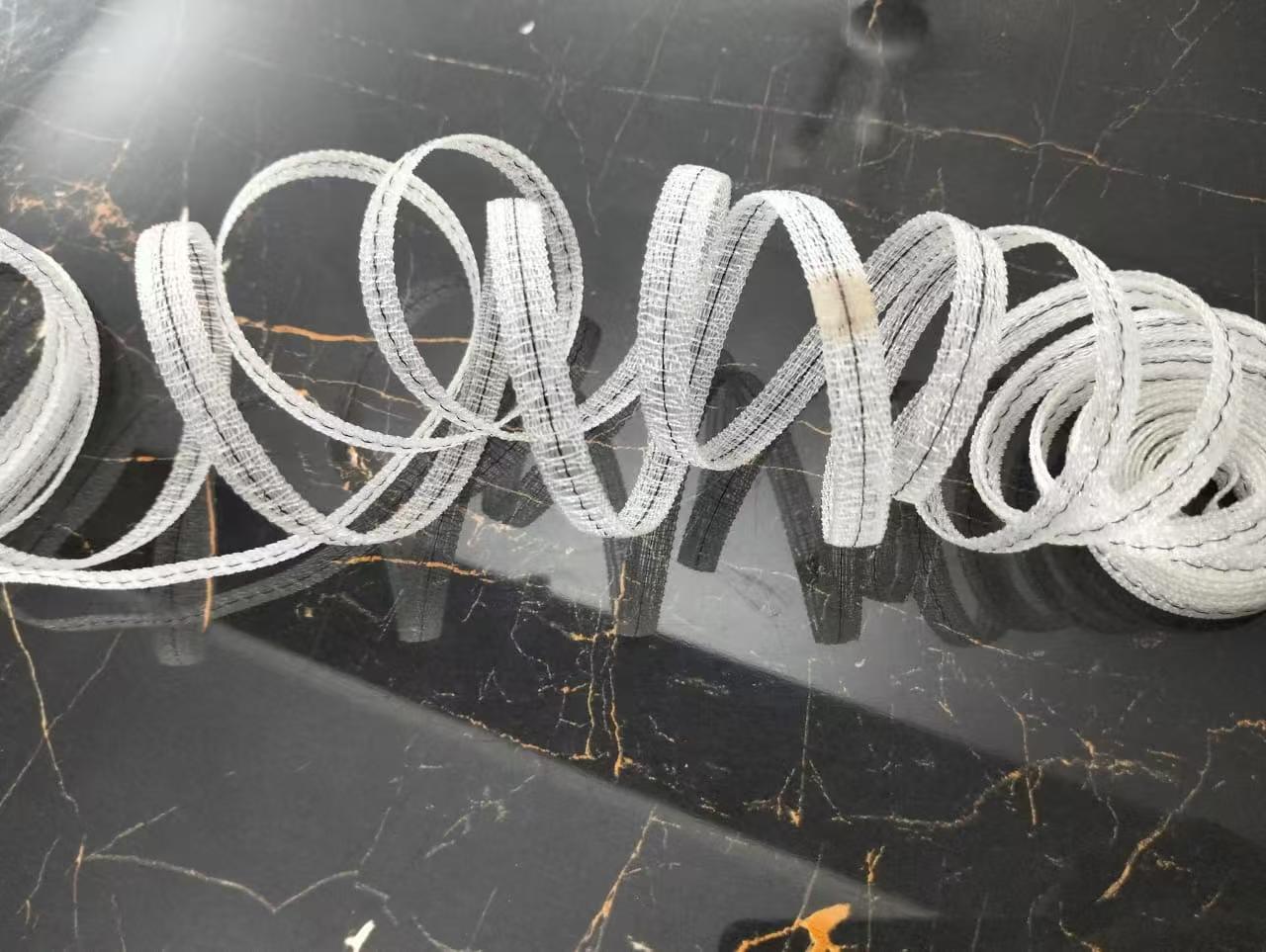

💎 Manufactured using three-layer lamination technology (wear layer + fiber reinforcement mesh + base layer), achieving tensile strength ≥8MPa and extending service life five times longer than traditional rubber belts.

⏳ Cost Optimization: Annual comprehensive usage cost reduced by over 40% through decreased downtime for material replacement.

🔬 5. Precision Drive Performance

🎯 Laser-calibrated straightness error <0.3mm/m with dynamic tension fluctuation within ±5%, ensuring zero material deviation during high-speed operation.

▶️ Technological Highlight: Patented radio frequency (RF) welding seamless joint technology completely eliminates material jamming risks associated with mechanical fasteners.

6. Eco-Friendly Sustainable Solution

♻️ Free from hazardous substances like halogens and heavy metals; end-of-life belts fully recyclable through pyrolysis regeneration technology.

🏆 Industry Benchmark: 60% lower carbon footprint compared to PVC materials, already included in supplier lists of multinational corporations such as Tesla and Apple.

Our company has three patents authorized and eight patents pending. In May 2019, we passed the Shanghai High-tech Achievement Transformation Project, and in September of the same year, we officially became a Shanghai High-tech Enterprise. Since our establishment, our company has been focusing on the industrial belt industry, focusing on innovation, and constantly developing new products, because we believe that innovation is the vitality of the enterprise.

Production Factory

As a manufacturer, we have a standard workshop of 2000 square meters, which has passed ISO9001 quality certificationIn production, we check every level and arrange professional quality inspection personnel to carry out strict quality inspection on the finished products to ensure that each manufactured product is a premium product. Usually, our factory has a large amount of inventory to provide customers with customized services to meet customer's short delivery requirements.

12 Years Industrial Belt Experience

During the 12 years of customer service, we have helped thousands of companies to provide countless solutions to belt problems. From the belt configuration of Mercedes-Benz's automobile production line, the installation and commissioning of the conveyor belt at Nike's logistics center, and the development and application of roll-up belts in steel mills and aluminum plants.We have accumulated a wealth of industrial belt industry experience, and these experiences have motivated continuously develop new products. Whether you are selecting a belt for a new machine or a problem with an existing belt, we are ready to provide you with professional advice and solutions.

Professional Staff

Professional team. Our employees are all professionally trained. Our professionalism and service of sales staff has won praise and recognition from customers. Any inquiry from you will be answered within 24 hours.

OEM/ODM Available

OEM/ODM order available. Reliable machinery has the experience capability and professional R&D team to make any OEM/ODM customer's project, responsible work shop managent follow up and supervise each other.