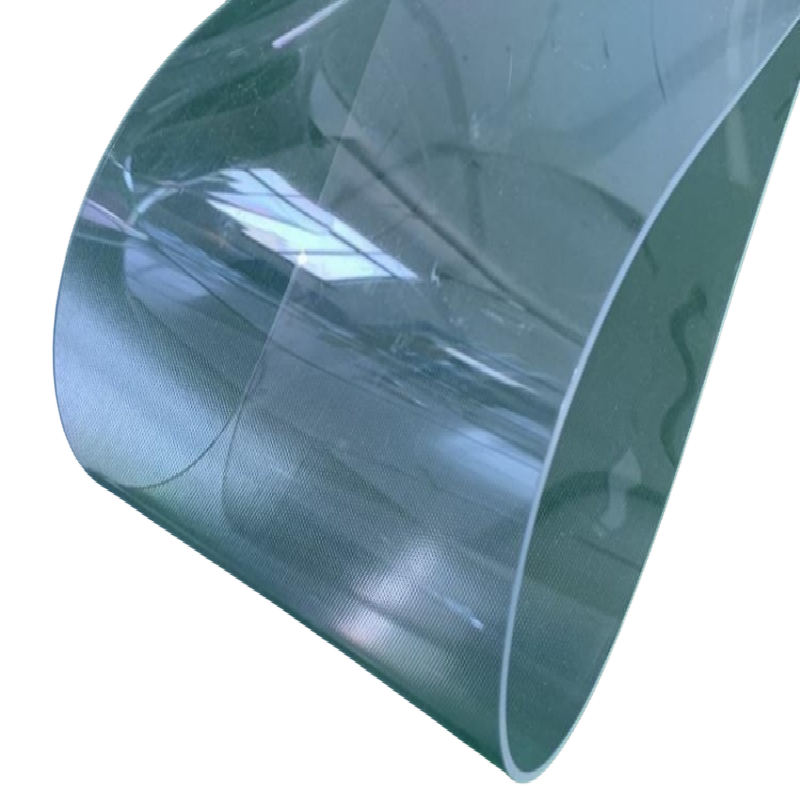

Transparent Conveyor Belt

Transparent Conveyor Belt

We are a Shanghai-based conveyor belt manufacturer with ISO-certified production in Huzhou, China. Our transparent PVC/PU belts enable real-time visual monitoring for food processing, pharmaceuticals, and electronics assembly—featuring anti-static properties, chemical resistance, and customizable dimensions (1–8mm thick, up to 2m wide). Precision-tracked designs ensure contamination-free operation at high speeds, while seamless splicing minimizes downtime. Trusted globally for compliance with FDA standards and reducing maintenance costs by 30%.

Call Us: +86-13916946090

Inquiry Now- Production Factory

- High Quality

- Good Price

- OEM/ODM

Details

I. Product Definition & Innovative Value

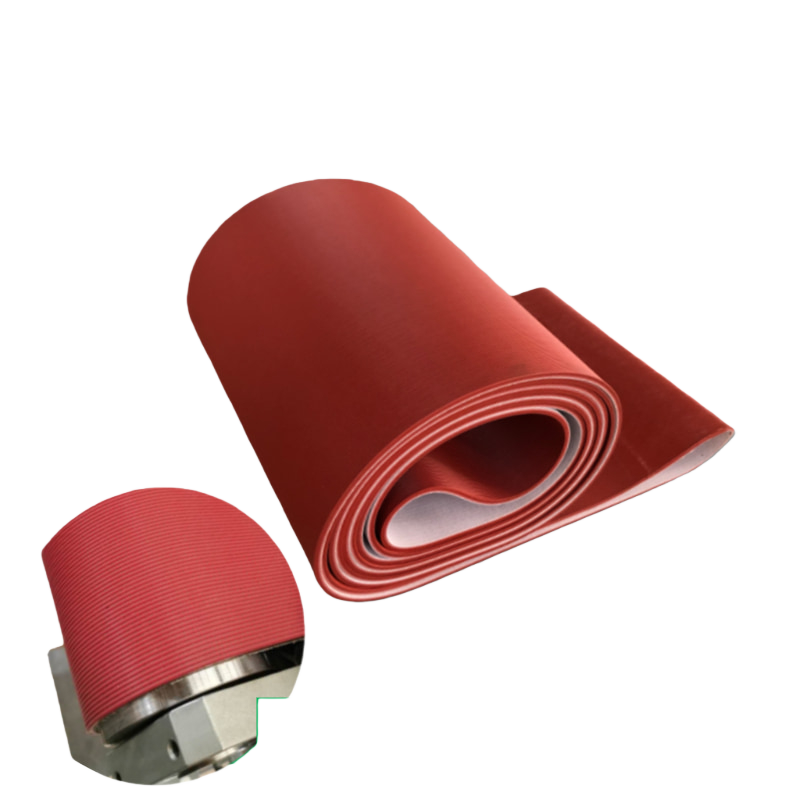

Our transparent conveyor belts are manufactured from optical-grade polyvinyl chloride (PVC) or thermoplastic polyurethane (PU) materials, specifically engineered for applications requiring visual monitoring, high hygiene standards, and automation integration. Unlike traditional rubber belts, their crystal-clear transparency allows real-time observation of material flow while meeting cleanroom requirements for dustlessness and easy cleaning. Nanoscale surface treatments provide low adhesion and self-lubricating properties, significantly improving production efficiency and reducing cross-contamination risks.

II. Core Advantages Analysis

| Advantage Area | Technological Breakthrough | Customer Benefits |

|---|---|---|

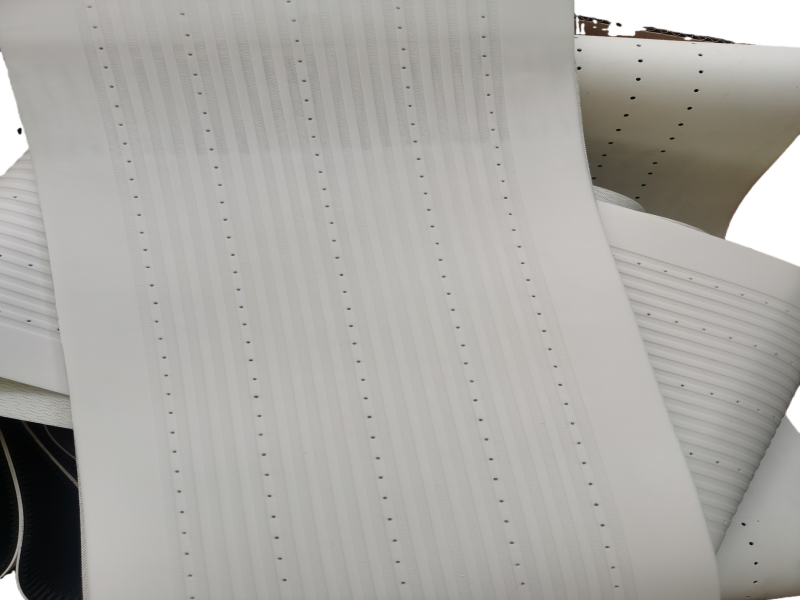

| Full Visibility | Light transmittance ≥92% (tested per ASTM D1003 standard); zero haze optical design compatible with cameras | Quality inspectors detect foreign objects without stopping machinery; automated vision systems accurately identify product defects |

| Food Safety Compliance | Conforms to FDA 21 CFR Part 177 and EU No. 10/2011 regulations; no plasticizer migration (ND≤0.01mg/kg) | Direct contact with ready-to-eat products like bread/candy fully compliant; eliminates false alarms in metal detectors |

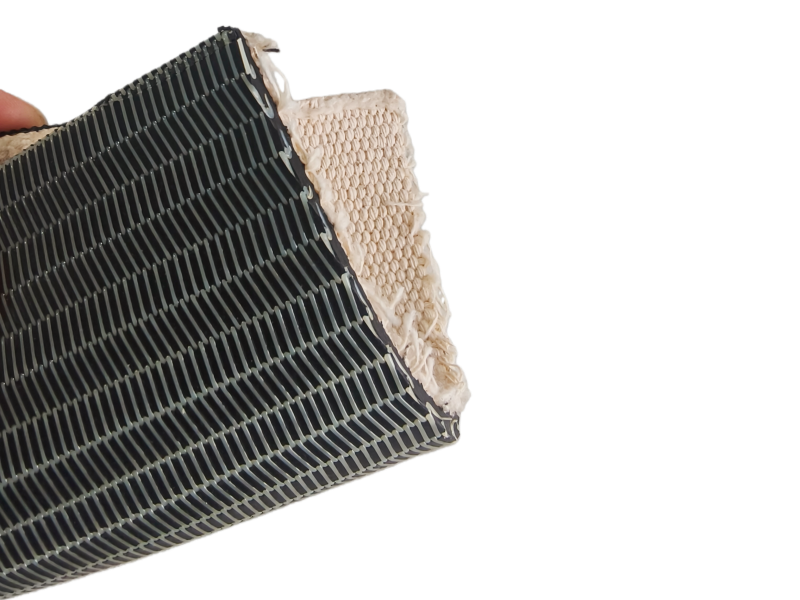

| Ultra-Durable Construction | Three-layer co-extrusion technology (wear layer + reinforced fiber network + base layer); stable operation from -40℃ to +85℃ | Freezing meat processing lines prevent cracking; high-temperature drying tunnels resist deformation |

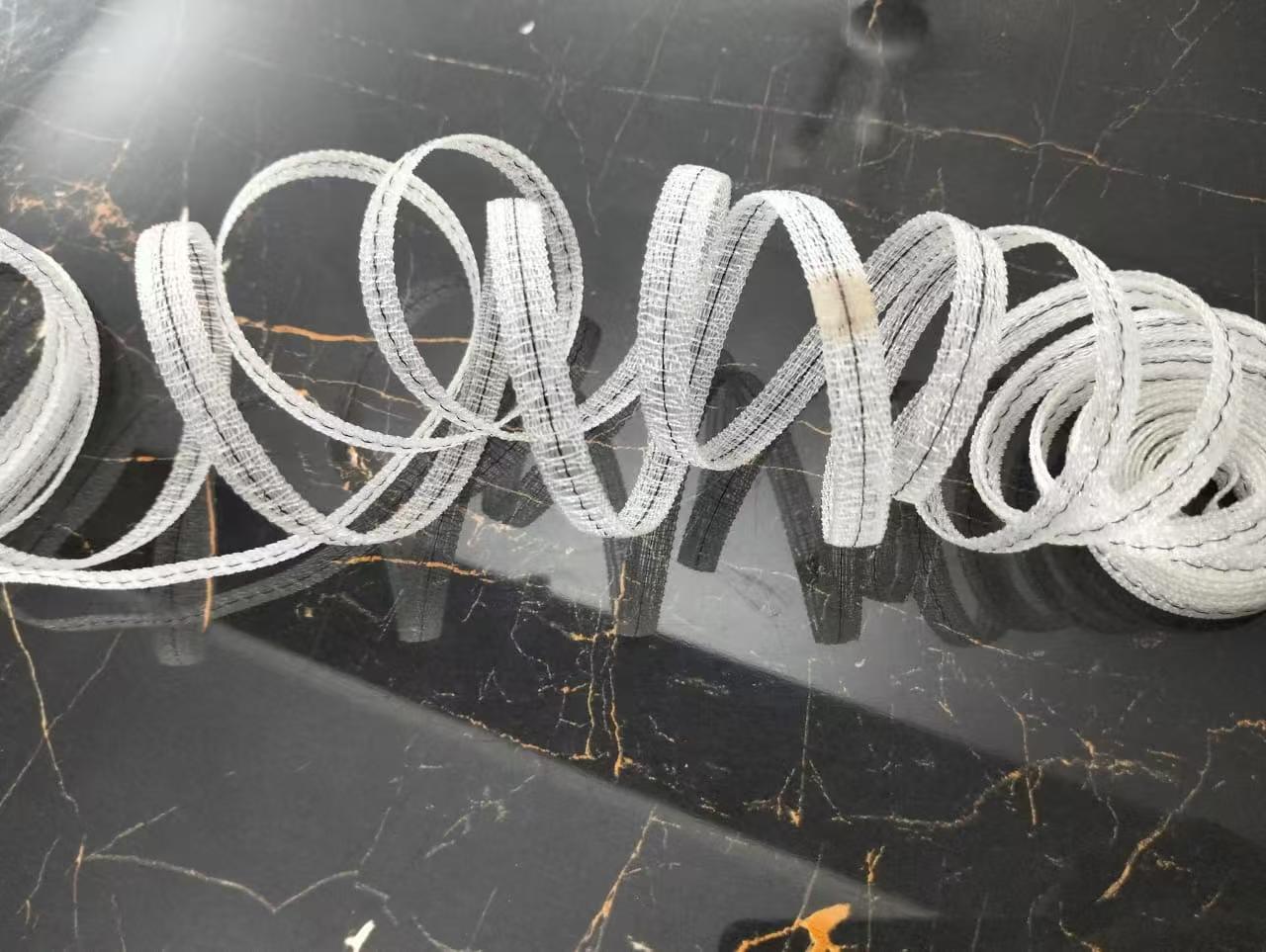

| Intelligent Tracking System | Edge-embedded permanent magnetic guide strips (accuracy ±0.5mm); dynamic tension auto-compensation device | Perfect alignment maintained during high-speed operation; reduces equipment downtime caused by misalignment by 70% |

| Eco Sustainability | Recyclable material content ≥65%; lifecycle carbon footprint reduced by 40% compared to conventional belts | Quantifiable emission reduction contributions for ESG reports; compliant with green procurement policies of multinational corporations like Apple/Tesla |

III.Key Technical Specifications Table

| Parameter | Standard Specification | Special Working Conditions Options | Testing Method |

|---|---|---|---|

| Max Working Width | 300mm / 600mm / 1200mm | Customizable up to 2000mm | DIN ISO 5295 |

| Thickness Tolerance | ±0.15mm | ±0.05mm (precision grade) | IPCE micrometer laser scanning |

| Min Driven Roller Diameter | Φ50mm | Φ25mm (micro version) | FEM finite element analysis simulation |

| Chemical Resistance | pH3-pH14 | Withstands 48-hour immersion in solvents like acetone/toluene without swelling | ASTM C1199 immersion test |

| Static Friction Coefficient | μ=0.25 (dry condition) | μ<0.18 (PTFE coated upgrade version) | GB/T 4618-2019 |

| UV Aging Lifespan | QUV accelerated test ≥5000 hours | Reinforced version up to 8000 hours | ISO 4892-3 cycle testing |

| Antimicrobial Treatment | Ag ion loading capacity 3ppm | Cu/Zn composite ion alternative | JIS Z 2801 sterilization rate test |

Why Us

Continuous Innovation

Our company has three patents authorized and eight patents pending. In May 2019, we passed the Shanghai High-tech Achievement Transformation Project, and in September of the same year, we officially became a Shanghai High-tech Enterprise. Since our establishment, our company has been focusing on the industrial belt industry, focusing on innovation, and constantly developing new products, because we believe that innovation is the vitality of the enterprise.

Production Factory

As a manufacturer, we have a standard workshop of 2000 square meters, which has passed ISO9001 quality certificationIn production, we check every level and arrange professional quality inspection personnel to carry out strict quality inspection on the finished products to ensure that each manufactured product is a premium product. Usually, our factory has a large amount of inventory to provide customers with customized services to meet customer's short delivery requirements.

12 Years Industrial Belt Experience

During the 12 years of customer service, we have helped thousands of companies to provide countless solutions to belt problems. From the belt configuration of Mercedes-Benz's automobile production line, the installation and commissioning of the conveyor belt at Nike's logistics center, and the development and application of roll-up belts in steel mills and aluminum plants.We have accumulated a wealth of industrial belt industry experience, and these experiences have motivated continuously develop new products. Whether you are selecting a belt for a new machine or a problem with an existing belt, we are ready to provide you with professional advice and solutions.

Professional Staff

Professional team. Our employees are all professionally trained. Our professionalism and service of sales staff has won praise and recognition from customers. Any inquiry from you will be answered within 24 hours.

OEM/ODM Available

OEM/ODM order available. Reliable machinery has the experience capability and professional R&D team to make any OEM/ODM customer's project, responsible work shop managent follow up and supervise each other.

Our company has three patents authorized and eight patents pending. In May 2019, we passed the Shanghai High-tech Achievement Transformation Project, and in September of the same year, we officially became a Shanghai High-tech Enterprise. Since our establishment, our company has been focusing on the industrial belt industry, focusing on innovation, and constantly developing new products, because we believe that innovation is the vitality of the enterprise.

Production Factory

As a manufacturer, we have a standard workshop of 2000 square meters, which has passed ISO9001 quality certificationIn production, we check every level and arrange professional quality inspection personnel to carry out strict quality inspection on the finished products to ensure that each manufactured product is a premium product. Usually, our factory has a large amount of inventory to provide customers with customized services to meet customer's short delivery requirements.

12 Years Industrial Belt Experience

During the 12 years of customer service, we have helped thousands of companies to provide countless solutions to belt problems. From the belt configuration of Mercedes-Benz's automobile production line, the installation and commissioning of the conveyor belt at Nike's logistics center, and the development and application of roll-up belts in steel mills and aluminum plants.We have accumulated a wealth of industrial belt industry experience, and these experiences have motivated continuously develop new products. Whether you are selecting a belt for a new machine or a problem with an existing belt, we are ready to provide you with professional advice and solutions.

Professional Staff

Professional team. Our employees are all professionally trained. Our professionalism and service of sales staff has won praise and recognition from customers. Any inquiry from you will be answered within 24 hours.

OEM/ODM Available

OEM/ODM order available. Reliable machinery has the experience capability and professional R&D team to make any OEM/ODM customer's project, responsible work shop managent follow up and supervise each other.

.png)