Conveyor belt maintenance plan

Updated: 2022-7-13

Precautions for starting conveyor

1、 Inspection before startup

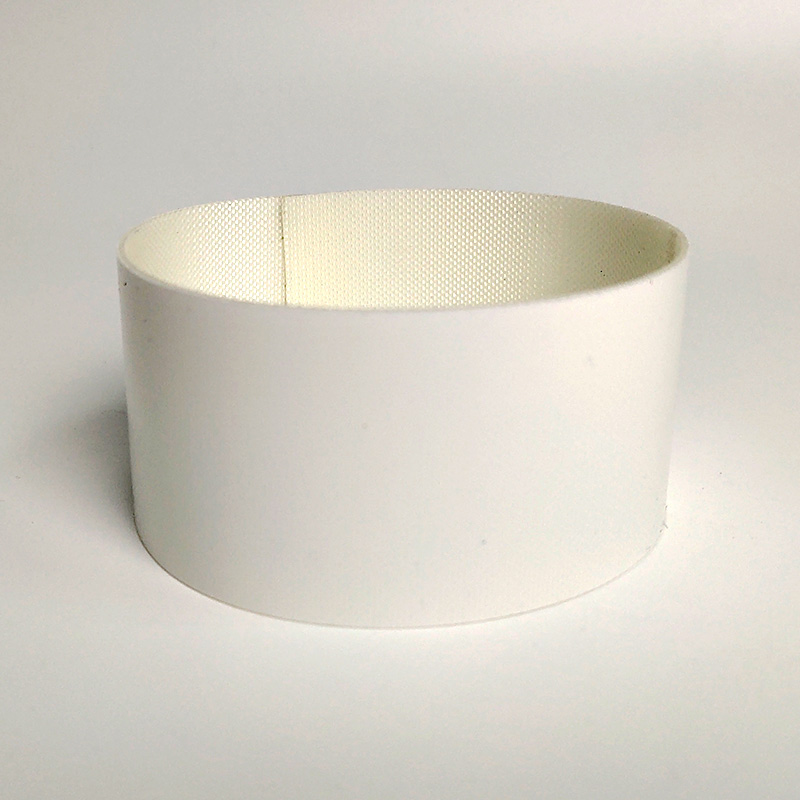

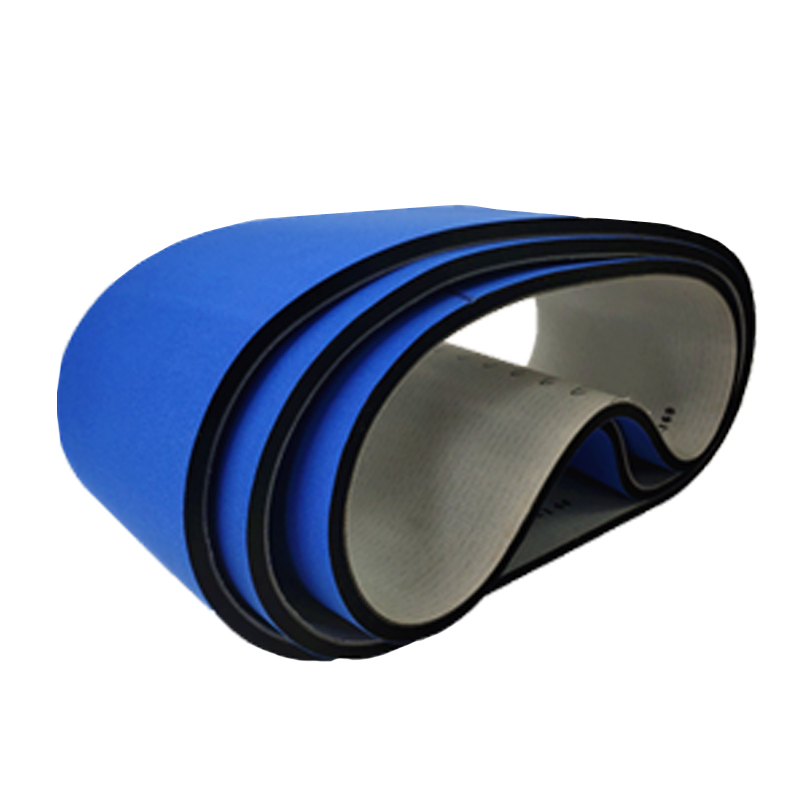

1. Check the conveyor belt for abnormal wear or damage.

2. The bottom overhang of the conveyor is in a certain normal position. (Whether abnormal)

3. Use the belt tension adjuster to check whether the tension of the tension adjuster is excessive and can exceed the strength of the belt (except for the push conveyor).

4. All supporting rollers can rotate smoothly.

5. Check whether the wheel is excessively worn.

6. Check whether there are foreign matters between the gear and the conveyor belt and clean them.

7. Check whether all supporting slideways and side guide devices have excessive or abnormal wear.

8. Whether the driving and driven shafts are integrated with the conveyor belt.

9. Check whether all lubricating parts are normal.

10. All parts of the conveyor system that need to be cleaned.

The importance of cleaning the conveyor

During the cleaning process of decontamination, the use of corrosive detergent to clean the conveyor belt should be avoided. Although detergent can clean the conveyor belt, it may change the plastic material and affect the service life.

In the cleaning process, if you want to remove the debris and impurities under the conveyor belt or inside the machine body, please make sure that the machine motor is turned off to avoid injury. Because in many production and transportation processes, the dough, syrup product debris and appearance packaging debris scattered in the system will cause pollution problems. External pollution, such as dust, sand and broken glass chips, will pollute the conveyor system and cause problems. Therefore, daily or periodic cleaning is very important. It is necessary to pay attention to the surrounding environment of the conveyor and regularly clean the conveyor system.

1、 Inspection before startup

1. Check the conveyor belt for abnormal wear or damage.

2. The bottom overhang of the conveyor is in a certain normal position. (Whether abnormal)

3. Use the belt tension adjuster to check whether the tension of the tension adjuster is excessive and can exceed the strength of the belt (except for the push conveyor).

4. All supporting rollers can rotate smoothly.

5. Check whether the wheel is excessively worn.

6. Check whether there are foreign matters between the gear and the conveyor belt and clean them.

7. Check whether all supporting slideways and side guide devices have excessive or abnormal wear.

8. Whether the driving and driven shafts are integrated with the conveyor belt.

9. Check whether all lubricating parts are normal.

10. All parts of the conveyor system that need to be cleaned.

The importance of cleaning the conveyor

During the cleaning process of decontamination, the use of corrosive detergent to clean the conveyor belt should be avoided. Although detergent can clean the conveyor belt, it may change the plastic material and affect the service life.

In the cleaning process, if you want to remove the debris and impurities under the conveyor belt or inside the machine body, please make sure that the machine motor is turned off to avoid injury. Because in many production and transportation processes, the dough, syrup product debris and appearance packaging debris scattered in the system will cause pollution problems. External pollution, such as dust, sand and broken glass chips, will pollute the conveyor system and cause problems. Therefore, daily or periodic cleaning is very important. It is necessary to pay attention to the surrounding environment of the conveyor and regularly clean the conveyor system.